Products

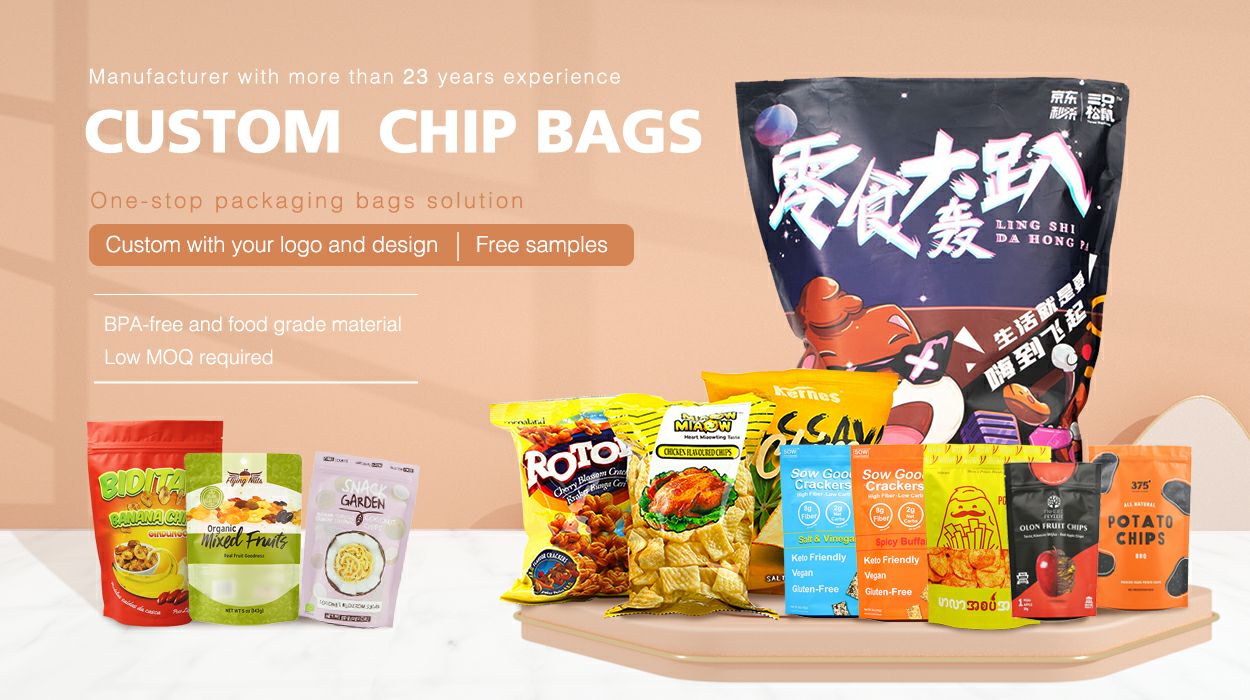

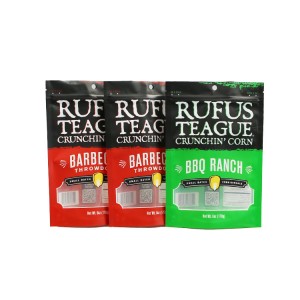

Custom 25g Plastic Stand Up Zipper Pouch Bag Food Packaging Black Bag For Snacks/ Popcorn

Custom 25g Plastic Stand Up Zipper Pouch Bag

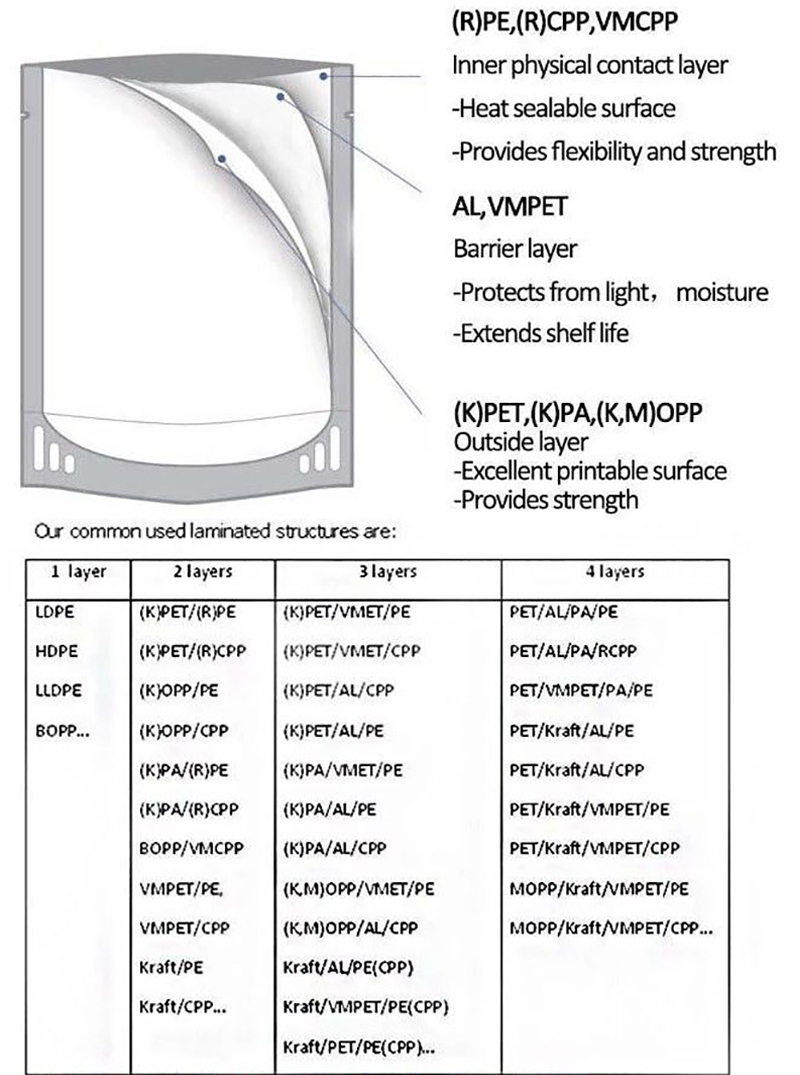

1. Material Options:

Polyethylene (PE): Commonly used for standard applications and offers good clarity.

Polypropylene (PP): Known for its durability and excellent moisture resistance.

PET/PE: A combination of polyester and polyethylene for enhanced barrier properties.

Metallized Films: Provide superior barrier properties, especially against light and moisture.

2. Stand-Up Design: The unique design allows the bag to stand upright, making it more visually appealing and space-efficient for product display.

3. Zipper Closure: The inclusion of a resealable zipper closure allows consumers to open and close the bag easily, ensuring the product remains fresh between uses.

4. Size and Capacity: Plastic stand-up zipper pouch bags come in various sizes and capacities to suit different products and portion sizes.

5. Printing and Branding:

Custom printing options allow you to add branding elements, logos, product information, and graphics to the bag's surface for effective marketing.

6. Transparency:

Clear or transparent areas on the bag can provide a view of the product inside, enhancing product visibility.

7. Tear Notches: Some bags feature tear notches to facilitate easy opening without the need for scissors or other tools.

8. Hanging Holes: For retail displays, some bags include built-in hanging holes or euro slots for peg hooks.

9. Gusseted Bottom: Some bags have a gusseted or expandable bottom that provides additional space for product volume.

10. Barrier Properties:

Depending on the material used, these bags can offer barrier properties against moisture, oxygen, and external contaminants, which help extend the shelf life of the products.

11. Customization:

You can customize these bags according to your specific requirements in terms of size, shape, printing, and branding.

12. Applications:

Plastic stand-up zipper pouch bags are versatile and used for a wide range of products, including snacks, cereals, grains, nuts, spices, powdered beverages, and non-food items like cosmetics and pet treats.

13. Sustainability:

Consider eco-friendly options, such as recyclable materials or biodegradable films, to align with sustainability goals and consumer preferences.

14. Quantity and Ordering:

Determine the quantity of bags needed and consider minimum order requirements when selecting a supplier or manufacturer.

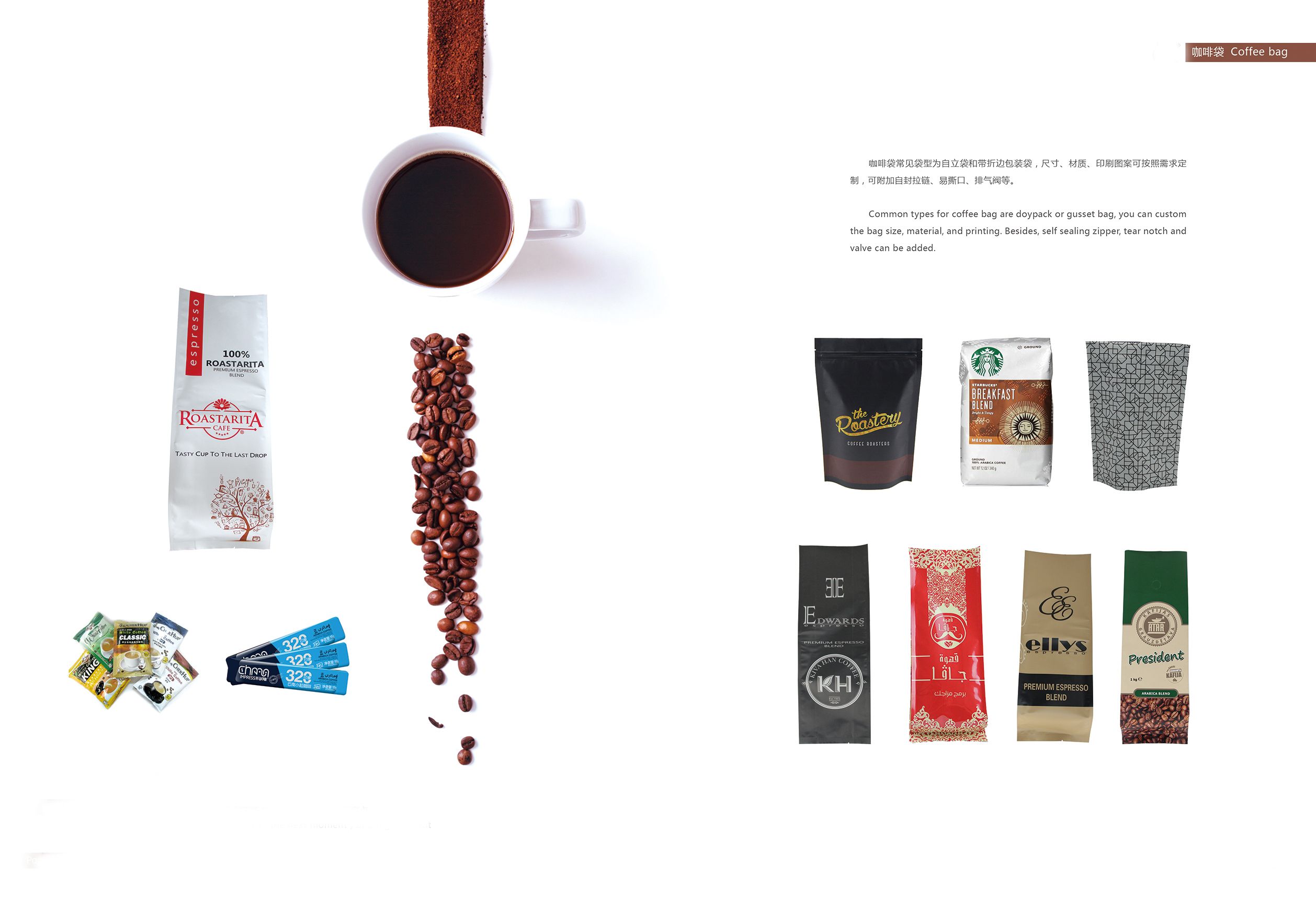

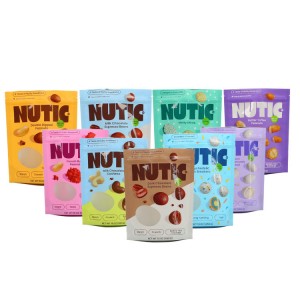

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.