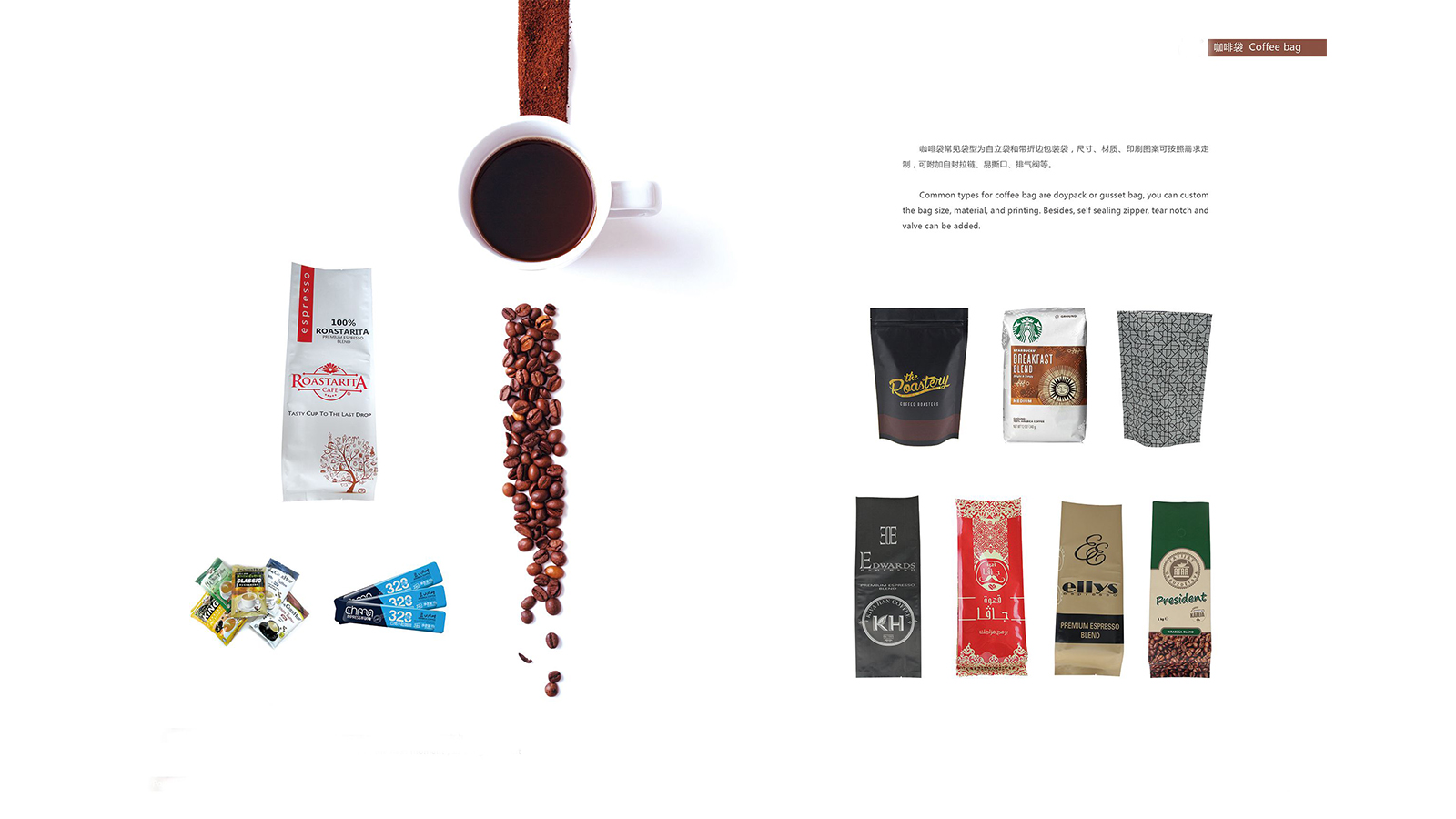

Products

Wholesale Special Shaped Bags Custom Printed 50g Jerky Stand Up Ziplock Bags

Custom Printed 50g Jerky Stand Up Ziplock Bags

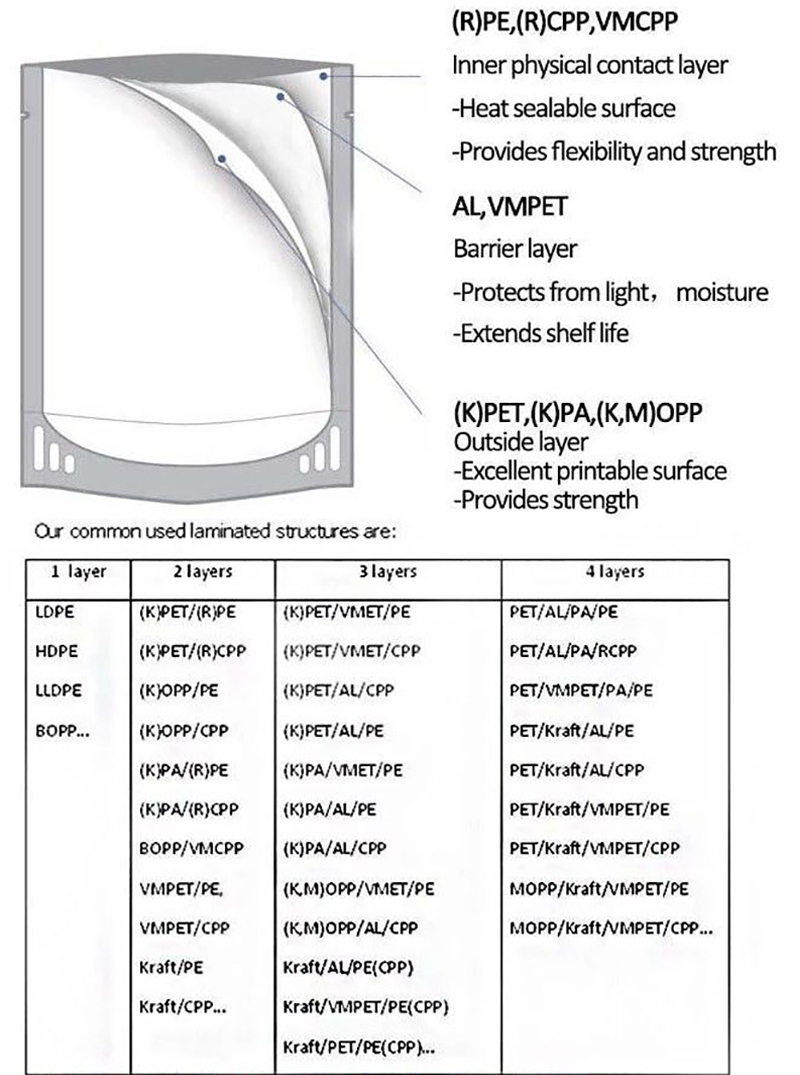

1. Material Composition:

Jerky bags are typically made from multi-layered materials to provide optimal protection against external factors such as moisture, light, oxygen, and odors. Common materials include laminated films, which can consist of layers of plastic, aluminum foil, and other barrier materials.

The choice of materials depends on factors such as the desired shelf life of the jerky, the storage conditions, and the printing requirements for branding and product information.

2. Barrier Properties:

One of the most crucial characteristics of jerky bags is their ability to create a barrier against moisture and oxygen. Moisture and oxygen can accelerate the degradation of jerky, leading to changes in texture, flavor, and overall quality.

High-quality jerky bags feature excellent barrier properties, effectively preventing moisture from entering the package and oxygen from reaching the jerky inside. This helps to extend the shelf life of the product and maintain its freshness.

3. Resealable Features:

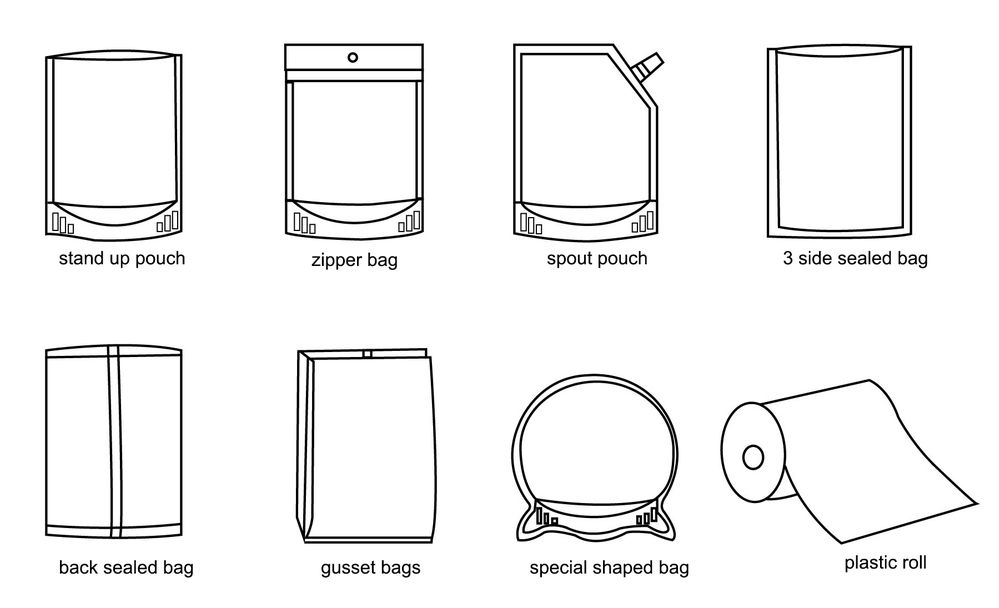

Many jerky bags are equipped with resealable closures such as zipper seals or press-to-close mechanisms. These features allow consumers to open and reseal the package multiple times, keeping the remaining jerky fresh between servings.

Resealable closures also enhance convenience and portability, enabling consumers to take their jerky on the go without worrying about spillage or the need for additional packaging.

4. Visibility and Transparency:

Jerky bags often incorporate transparent or semi-transparent windows to provide consumers with a clear view of the product inside. This allows customers to inspect the appearance and quality of the jerky before making a purchase decision.

Transparency also serves as a marketing tool, as it allows brands to showcase the texture and color of their jerky, enticing consumers with visually appealing packaging.

5. Durability and Strength:

Jerky bags are designed to withstand the rigors of transportation, handling, and storage. They are constructed from durable materials that offer sufficient strength and puncture resistance to protect the jerky from damage.

The durability of jerky bags is especially important for products that are sold in bulk or distributed through e-commerce channels, where the packaging may be subjected to rough handling during shipping.

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

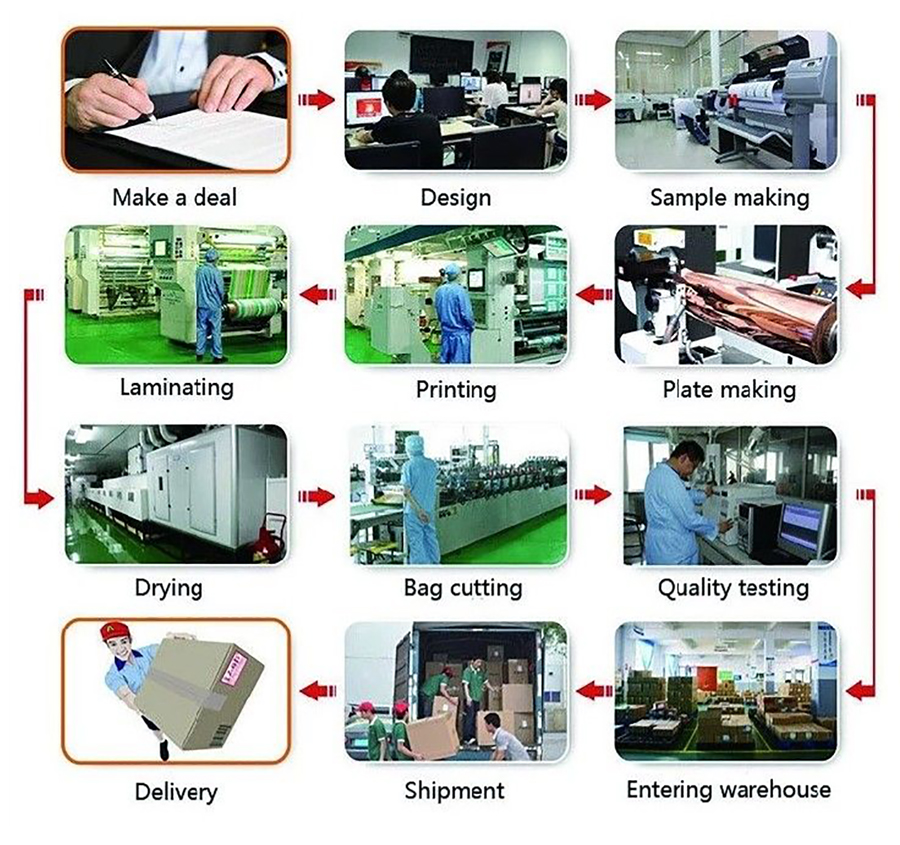

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.