Products

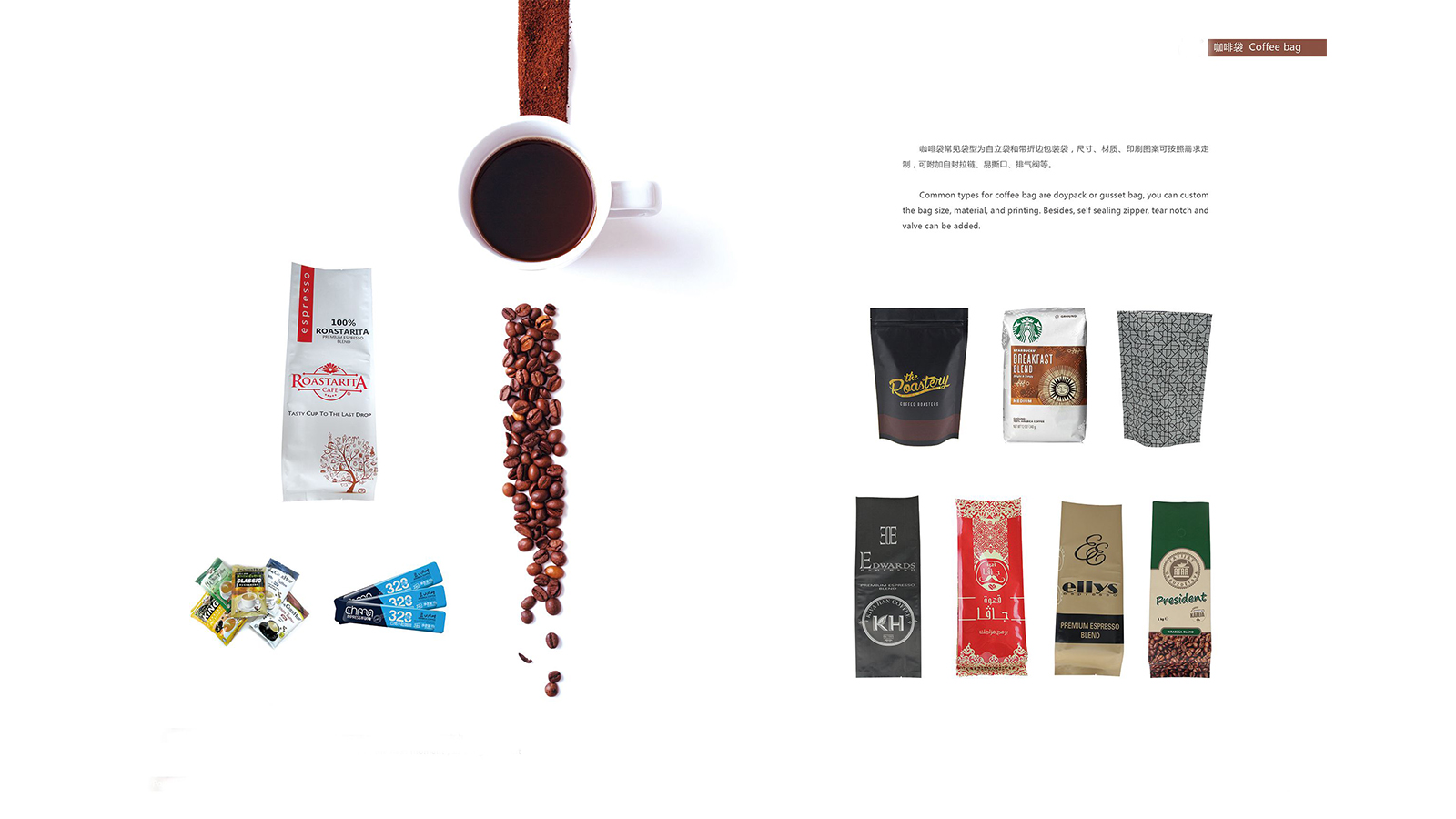

Wholesale Custom Mylar Packaging Food Grade Flat Bags

Custom Mylar Packaging Bag

1. Structure and Design:

Sealing Mechanism: These bags are sealed on three sides, leaving one side open for filling. Once the contents are placed inside, the fourth side can be sealed using heat or adhesive, ensuring the package is airtight and secure.

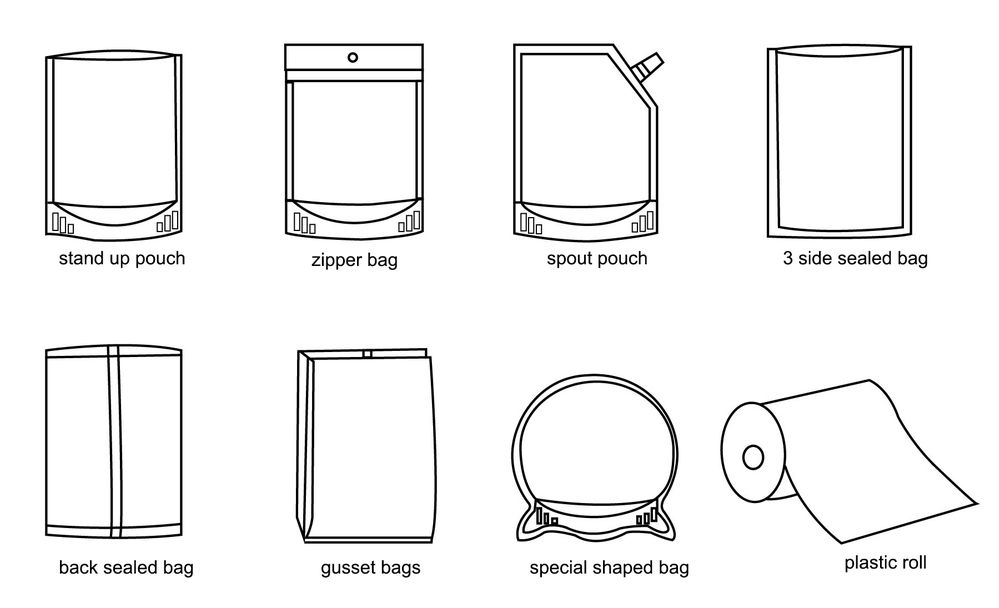

Flexibility in Size and Shape: They can be manufactured in various sizes and shapes to accommodate different products, ranging from small snacks to larger items. The ability to customize the dimensions makes them suitable for a wide range of applications.

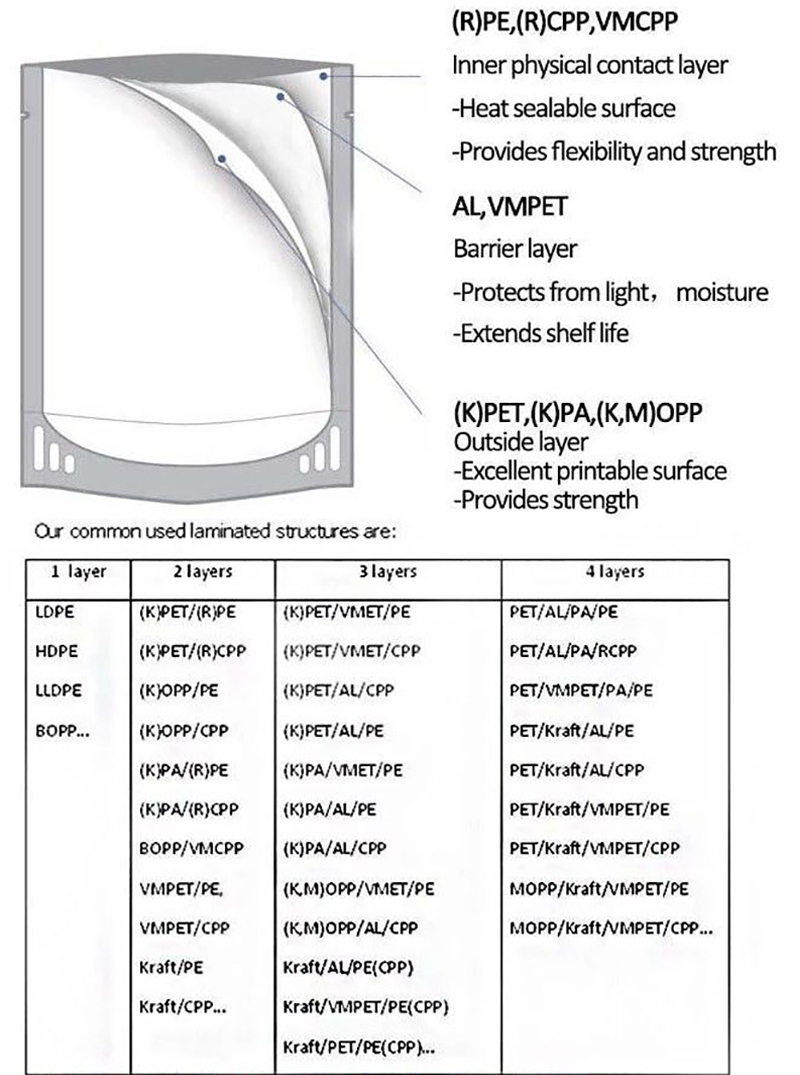

Material Variety: Three-sided sealing bags can be made from various materials such as plastic, aluminum foil, and composite films. The choice of material depends on the product's needs, such as moisture barrier, durability, and transparency.

2. Protection and Preservation:

Barrier Properties: These bags offer excellent protection against environmental factors like moisture, oxygen, and light. This is particularly important for food products and pharmaceuticals, as it helps in preserving freshness, potency, and shelf life.

Tamper-Evident Features: The secure sealing ensures that the contents are protected from tampering. Some designs include features like tear notches or resealable zippers, which provide added convenience and security for the end-user.

3. Convenience and Usability:

Easy to Fill and Seal: The open-end design simplifies the process of filling the bag, whether done manually or through automated machinery. Once filled, the sealing process is straightforward, making it an efficient packaging solution for manufacturers.

User-Friendly: Consumers find these bags easy to open and use. Features like tear notches make them simple to open without the need for scissors or other tools. Resealable options add to their convenience, allowing for repeated use while maintaining the integrity of the product.

4. Cost-Effectiveness:

Economical Production: The manufacturing process for three-sided sealing bags is relatively simple and cost-effective. The materials used are often less expensive than those required for more complex packaging solutions.

Reduced Material Waste: Since these bags are typically made from thin layers of material, they generate less waste compared to rigid packaging options. This not only reduces production costs but also minimizes environmental impact.

5.Versatility and Applications:

Wide Range of Uses: Three-sided sealing bags are suitable for a diverse array of products. They are commonly used in the food industry for packaging snacks, dried fruits, spices, and ready-to-eat meals. In the pharmaceutical industry, they are used for medical devices and health supplements.

Customization Options: These bags can be easily customized with branding, printing, and labeling. This allows companies to create visually appealing packages that attract consumers and convey important information about the product.

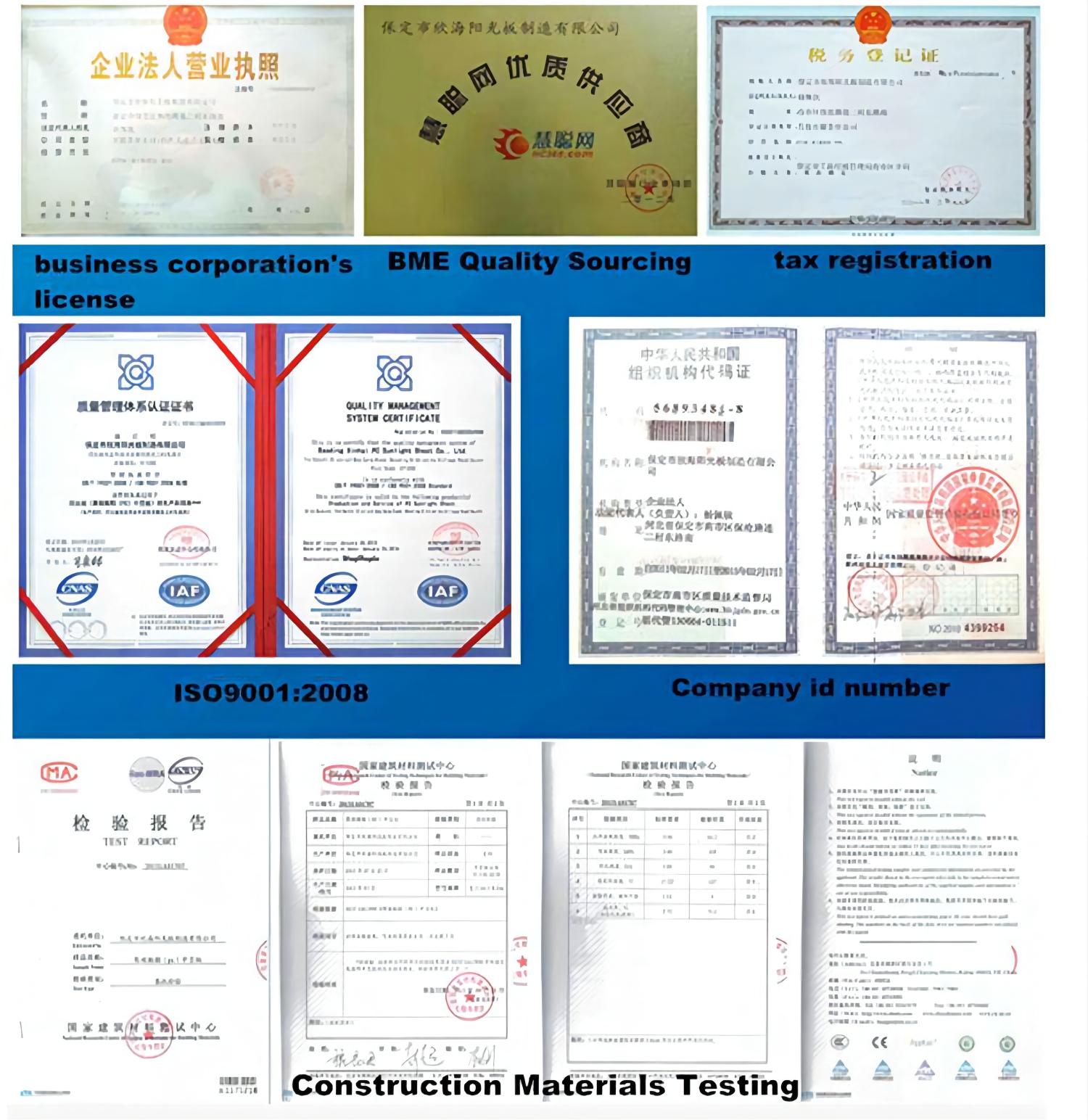

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

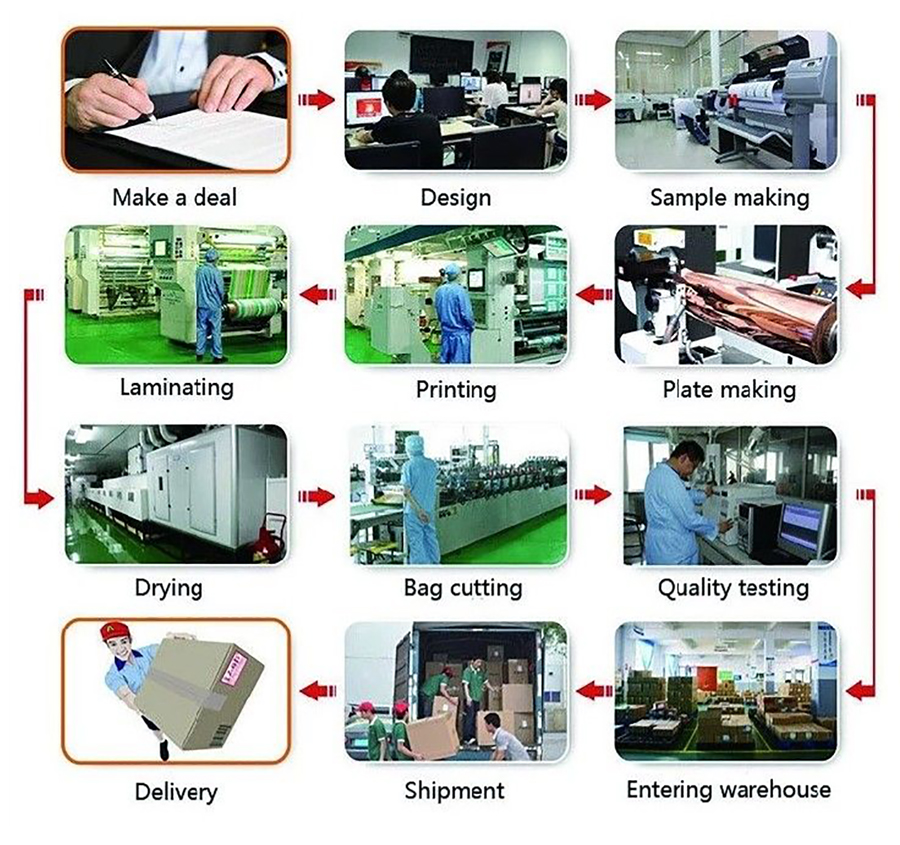

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.