Products

Three side seal bag with hang holes hot seal fruit chips pouch

Three Side Seal Bag With Hang Holes Hot Seal Fruit Chips Pouch

Sealing Method:Three-side seal bags are named for their sealing method. They have three sides that are heat-sealed, creating a secure closure while leaving the fourth side open.

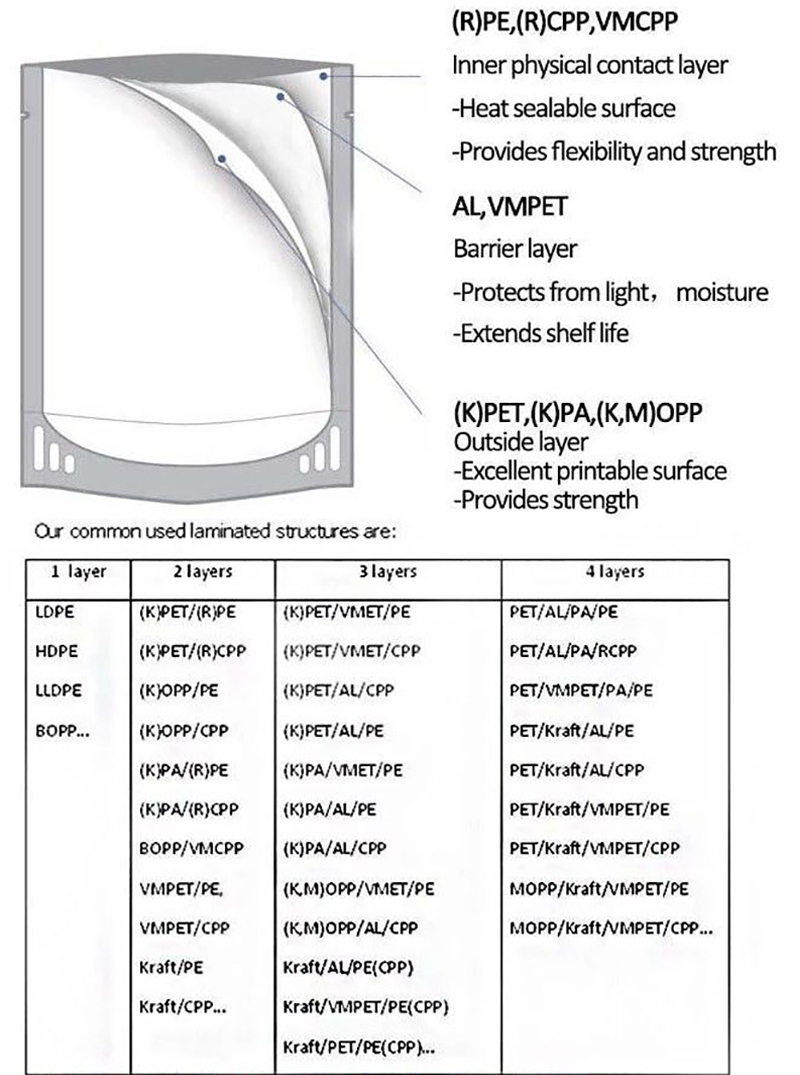

Materials:These bags can be made from various materials, including plastic films such as polyethylene (PE), polypropylene (PP), polyester (PET), or laminated films. The choice of material depends on the product being packaged and its specific requirements.

Customization:Three-side seal bags can be custom designed and printed with branding, product information, graphics, and decorative elements. This allows for effective product marketing and branding.

Size:They are available in a wide range of sizes, making them suitable for packaging items of different dimensions, from small sachets to larger bags.

Flat Appearance:These bags have a flat appearance when empty and are typically used for products that do not require a gusset or a stand-up structure.

Sealing Options:Depending on the material and the product being packaged, three-side seal bags can be sealed using heat, pressure, or adhesive methods. Zipper closures or tear notches can also be added for convenience.

Visibility:Some three-side seal bags have a transparent front panel or window, allowing customers to see the contents, which is particularly useful for retail packaging.

Versatility:They are used for a wide range of products, including snacks, confectionery, pharmaceuticals, cosmetics, powdered products, small hardware items, and more.

Single-Use or Resealable:Depending on the design and additional features, these bags can be single-use or resealable, allowing for easy access and freshness retention.

Cost-Effective:Three-side seal bags are often cost-effective packaging solutions, especially for products with lower production quantities.

Regulatory Compliance:Ensure that the materials and design of the bag comply with relevant food safety and packaging regulations in your region.

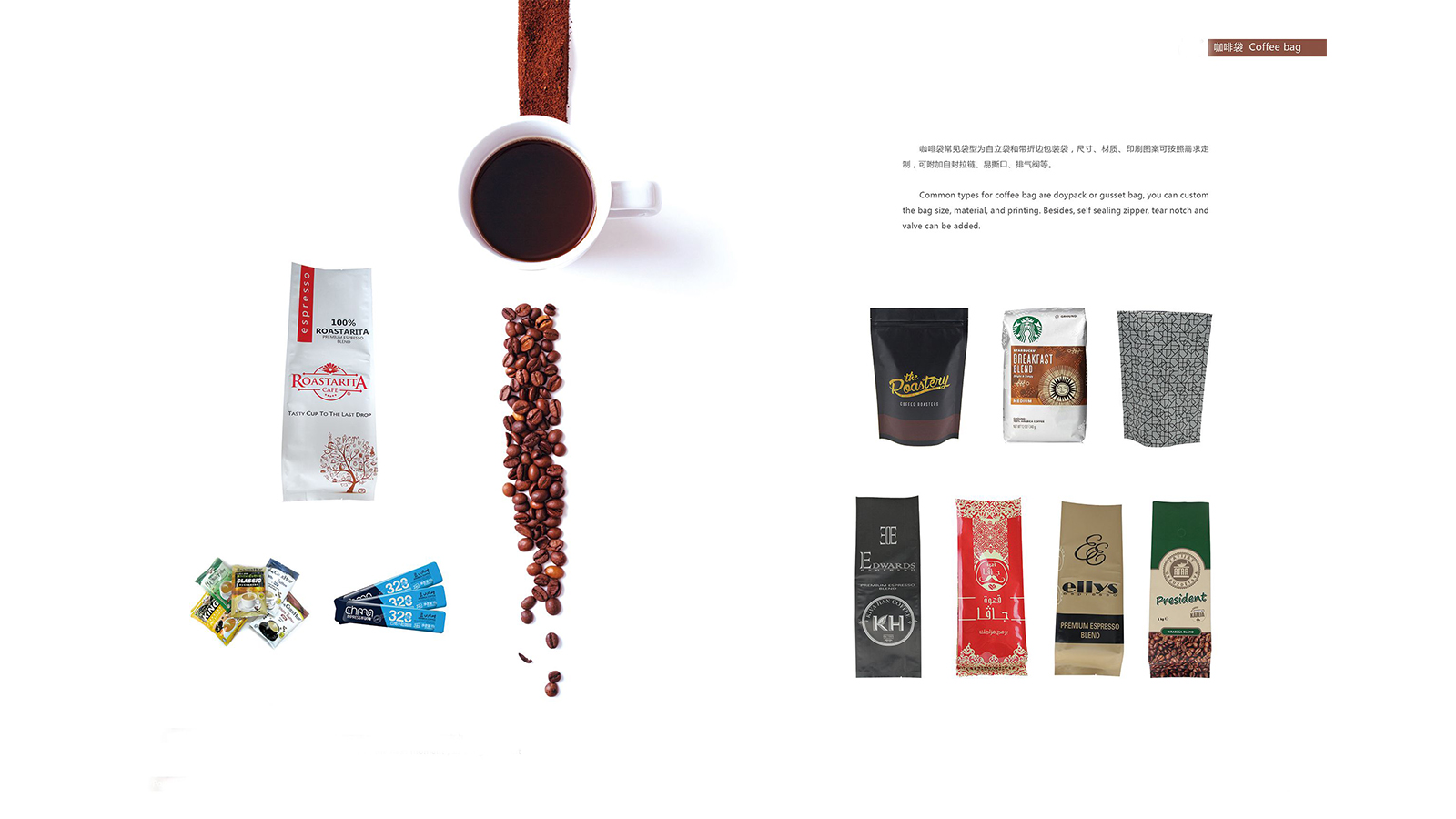

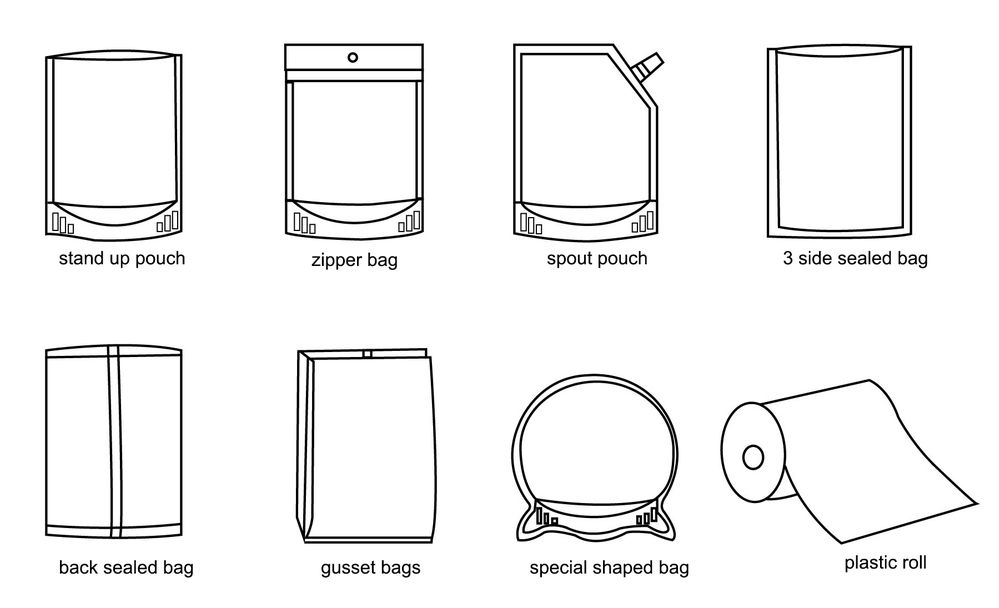

We also have the following range of bags for your reference.

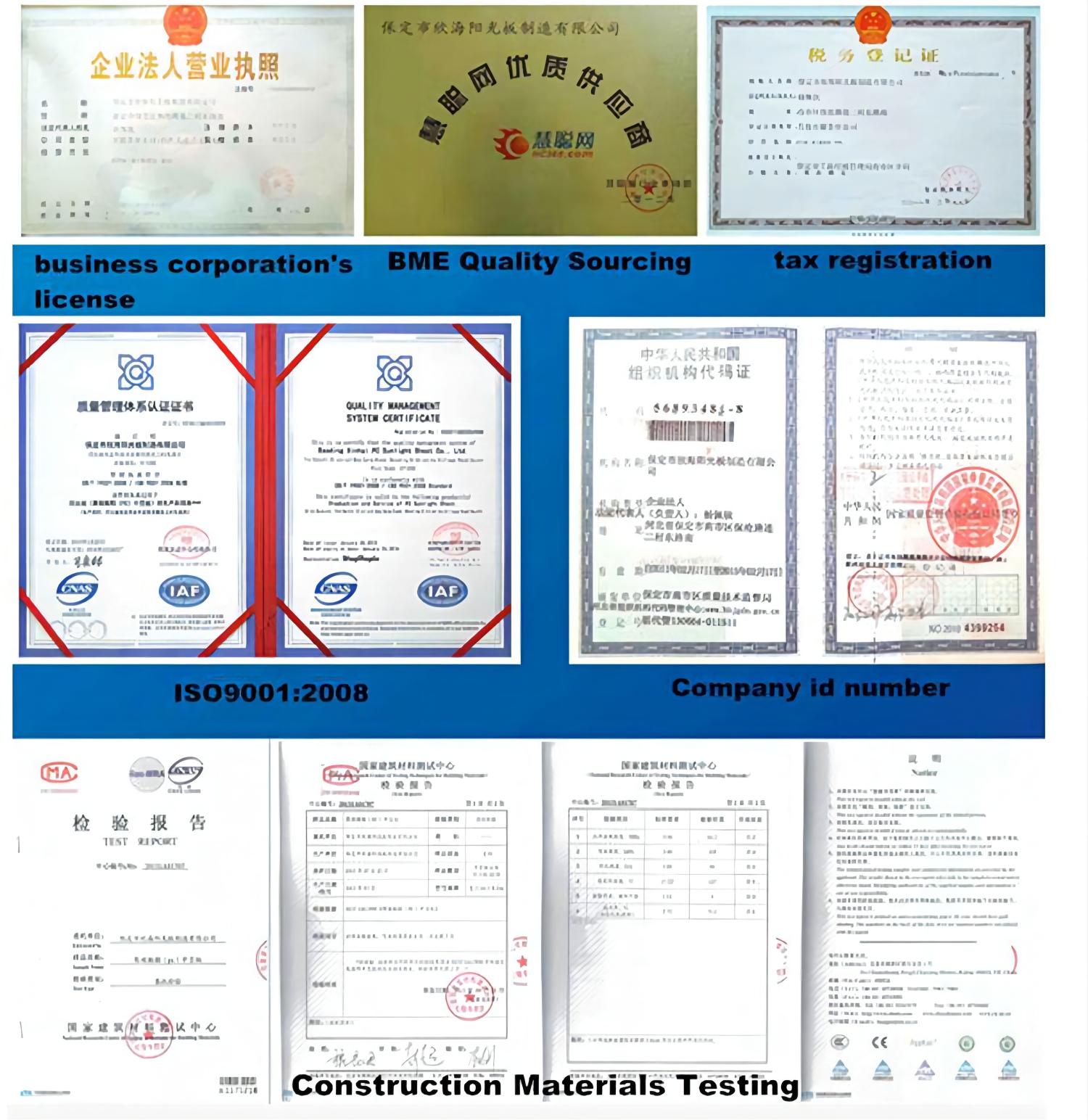

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

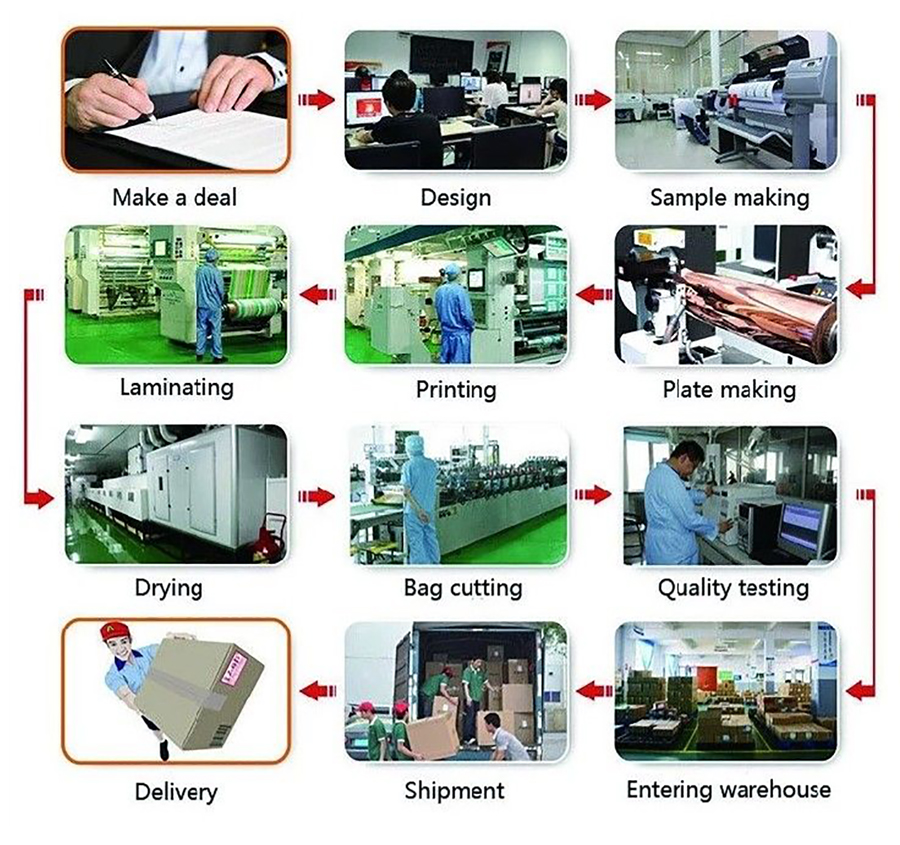

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.