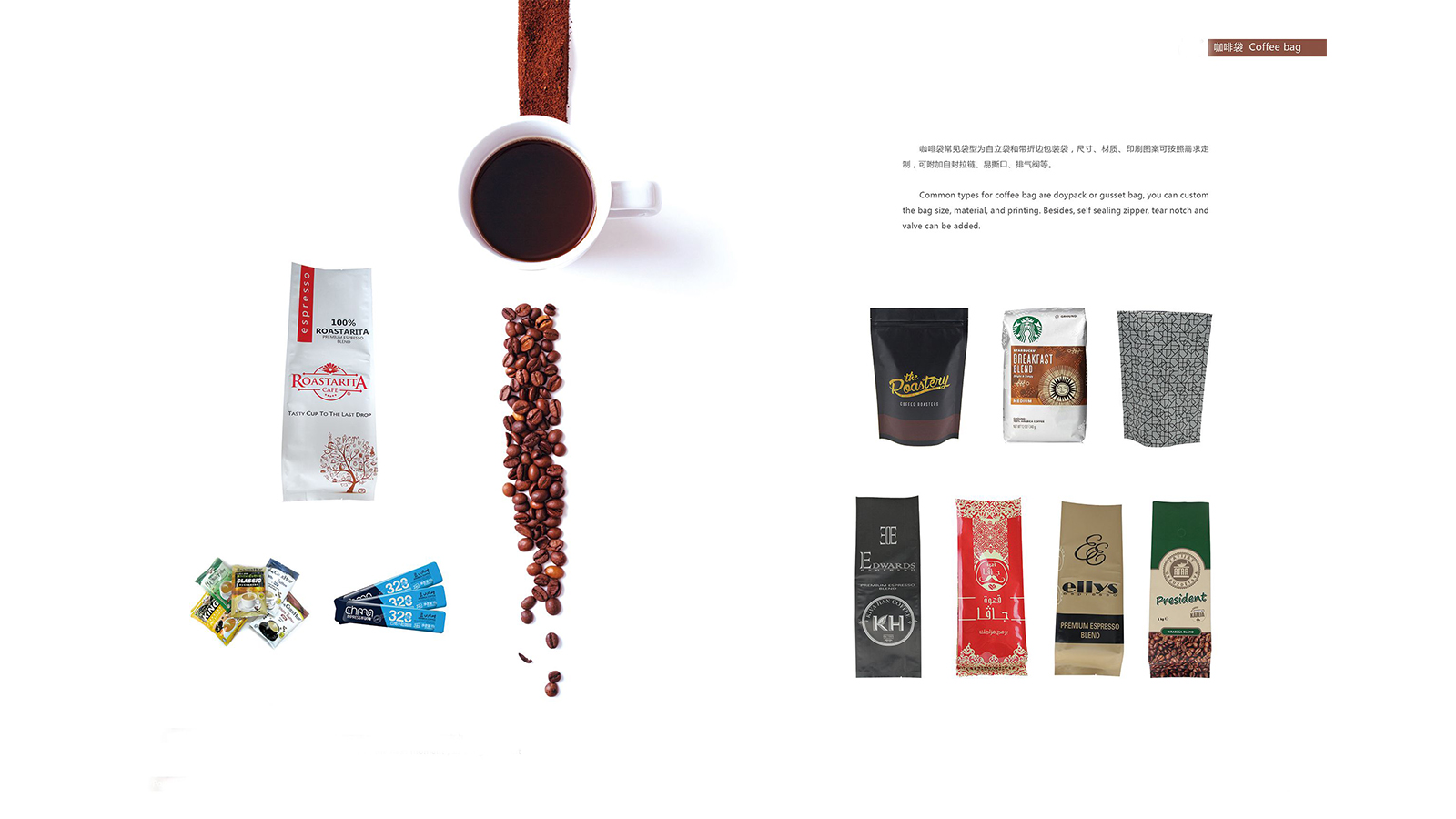

Products

Super Designs Dried Fruits Kraft Paper Packaging Pouch

Dried Fruits Kraft Paper Packaging Pouch

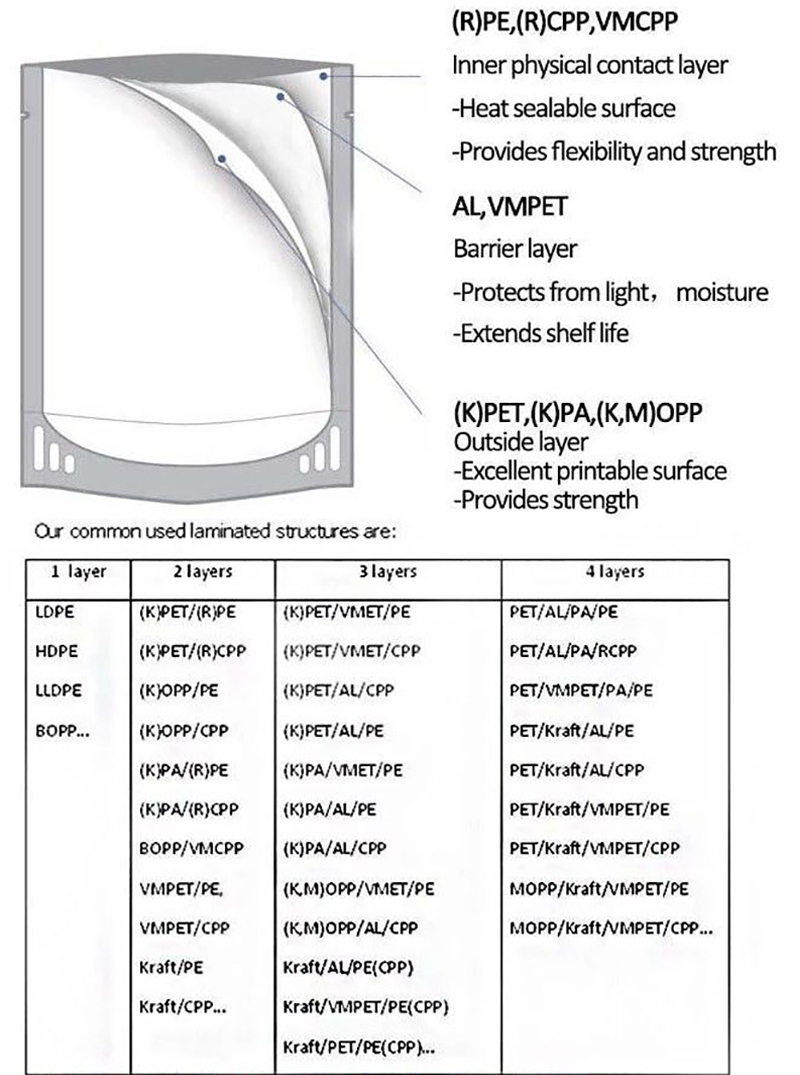

Material: Kraft paper is the main material used for these bags. It is a natural biodegradable material derived from wood pulp and is an environmentally friendly choice. Some kraft paper may have a laminated inner layer to provide additional protection against moisture and external factors.

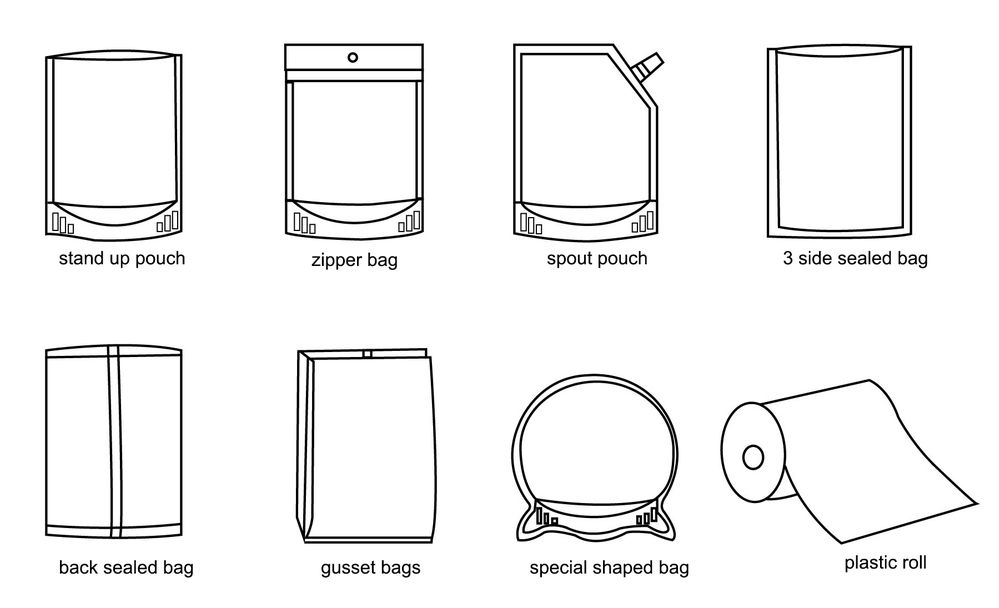

Flat pouch design: These pouches are usually flat and rectangular, saving space and easy to stack on store shelves or during storage. Graphic design also allows for effective printing and branding.

Sealing: Dried fruit bags are usually available in a variety of sealing options, such as resealable zip locks, adhesive seals, or tin knots. The resealable closure helps maintain the freshness of the dried fruit and allows easy access by consumers.

Size changes: Dried fruit bags are available in various sizes to accommodate different quantities of products. Small bags are suitable for personal service, while large bags are ideal for family size or bulk packaging.

Barrier: Many dried fruit bags are equipped with laminates or barriers to protect the fruit from moisture, oxygen, light and other environmental factors that affect its quality and shelf life.

Clear Windows: Some bags feature clear Windows, made of clear plastic or degradable film. This window allows consumers to see what's inside, making it easier to identify the product and check its freshness.

Custom printing: Manufacturers can customize the brand, product information, nutritional content and other relevant details on the kraft paper bag. Appealing design and branding can help engage consumers and convey important product messages.

Sustainability: The emphasis on the environmental nature of kraft paper and any sustainability certification can be a selling point for brands catering to environmentally conscious consumers.

Heat seal: Certain kraft paper bags are heat seal, providing a secure closing and tampering with the obvious packaging. Heat seal ensures that the bag remains sealed before the consumer opens it.

Food safety: Ensure that the packaging bag meets the food safety regulations and is suitable for direct contact with food. This includes the use of food-grade materials and inks.

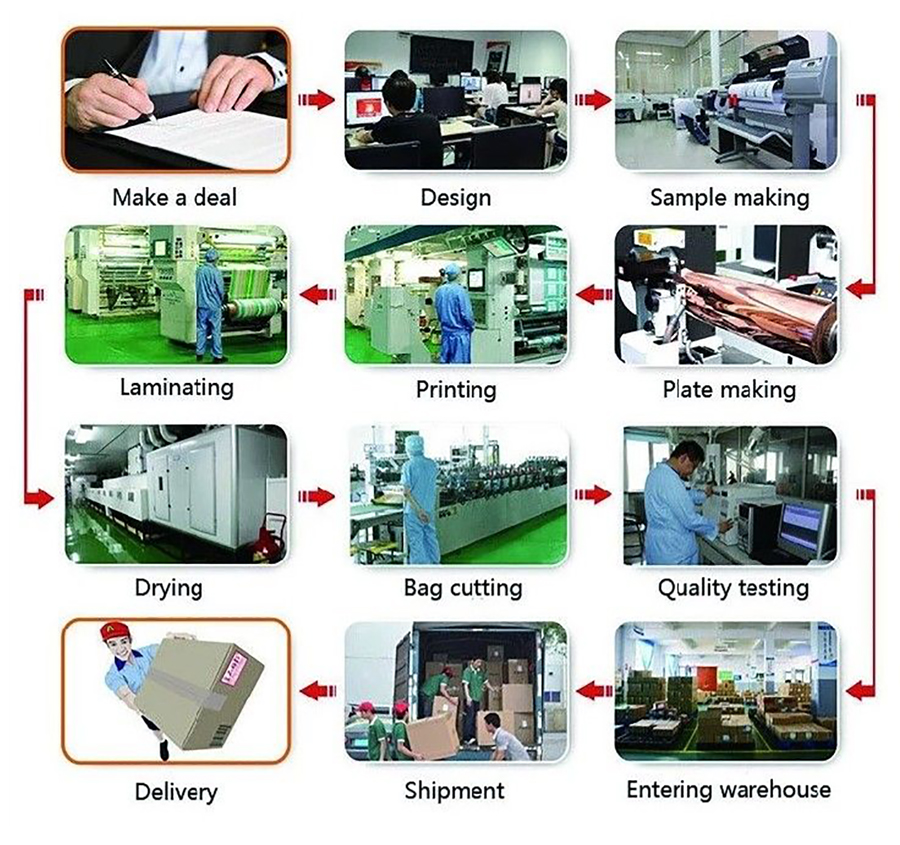

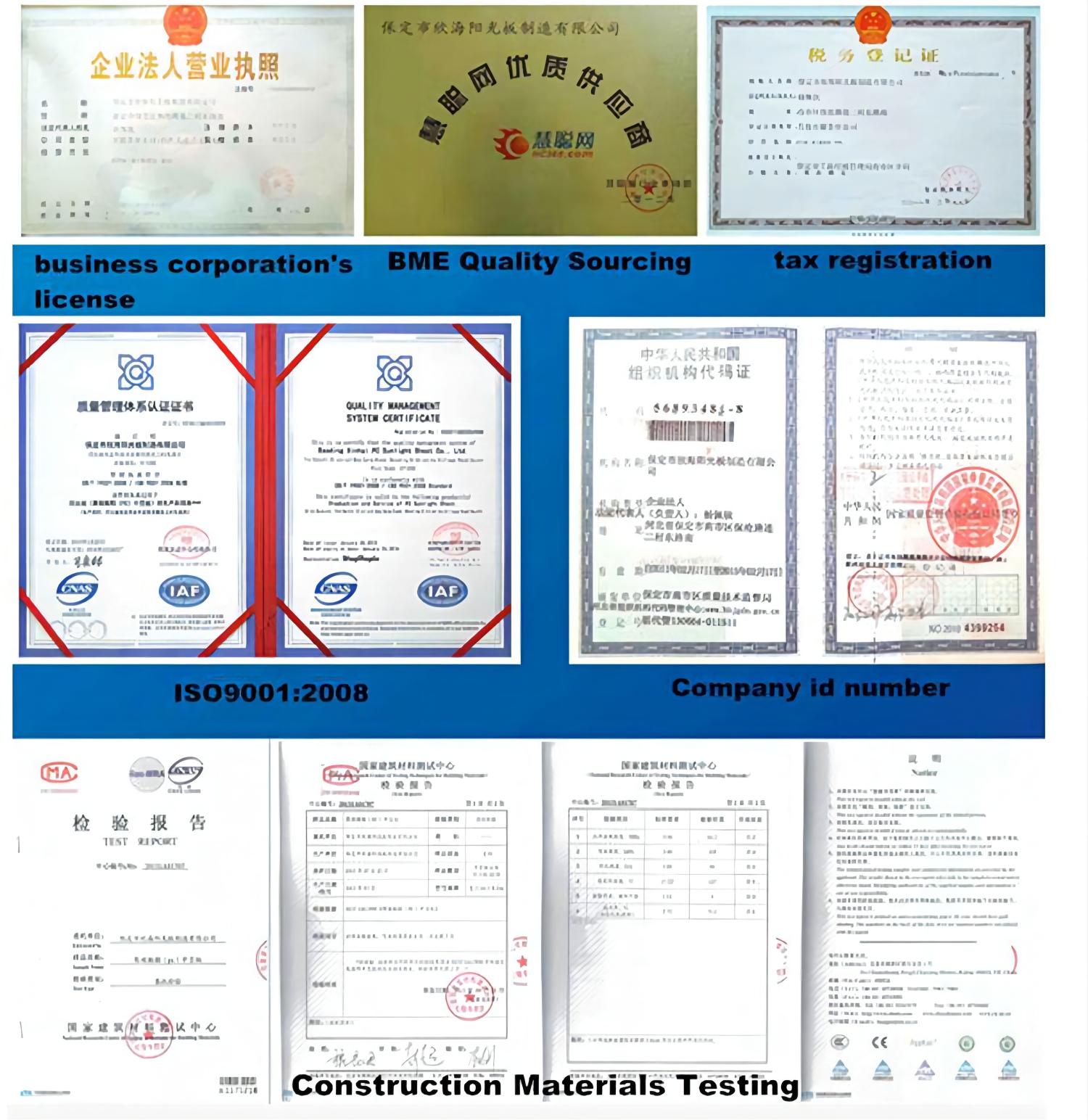

Quality control: Strict quality control measures are implemented in the production process to prevent defects and ensure that the packaging bag effectively protects the dried fruit.

We also have the following range of bags for your reference.

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.