Products

90g 250g 500g 1000g Powder Custom Packaging Custom Stand Up Pouch With Zipper Bags

1. Material: Stand-up pouches are typically made from multi-layer laminated materials that provide barrier properties to protect the contents from factors like moisture, oxygen, light, and odors. Common materials include:

Polyethylene (PE): Provides good moisture resistance and is often used for dry snacks and pet food.

Polypropylene (PP): Known for its heat resistance, making it suitable for microwaveable products.

Polyester (PET): Offers excellent oxygen and moisture barrier properties, ideal for products with longer shelf life requirements.

Aluminum: Used as a layer in laminated pouches to provide an excellent oxygen and light barrier.

Nylon: Offers puncture resistance and is often used in high-stress areas of the pouch.

2. Barrier Properties: The choice of materials and the number of layers in the pouch determine its barrier properties. Customizing the pouch to provide the right level of protection for the product inside is crucial to ensure product freshness and quality.

3. Size and Shape: Stand-up pouches come in various sizes and shapes, allowing you to choose the dimensions that best fit your product. The pouch's shape can be tailored to be round, square, rectangular, or custom die-cut to match your branding.

4. Closure Options: Stand-up pouches can feature various closure options, such as zipper seals, resealable tape, press-to-close mechanisms, or spouts with caps. The choice depends on the product and convenience for the consumer.

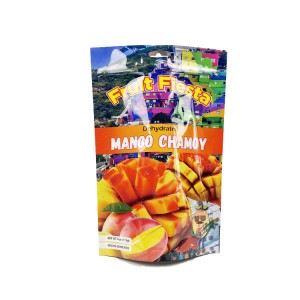

5. Printing and Customization: Custom stand-up pouches can be fully customized with high-quality printing, including vibrant graphics, branding, product information, and imagery. This customization helps your product stand out on the shelf and communicates key information to consumers.

6. Clear Windows: Some pouches feature clear windows or panels, allowing consumers to see the product inside. This is particularly useful for showcasing the contents of the pouch, such as snacks or cosmetics.

7. Hanging Holes: If your product is displayed on peg hooks, you can incorporate hanging holes or euroslots into the pouch design for easy retail display.

8. Tear Notches: Tear notches are pre-cut areas that make it easy for consumers to open the pouch without the need for scissors or knives.

9. Stand-Up Base: The design of the pouch includes a gusseted or flat bottom that allows it to stand upright on its own. This feature enhances shelf visibility and stability.

10. Environmental Considerations: You can choose eco-friendly options, such as recyclable or compostable materials, to align with sustainability goals.

11. Usage: Consider the intended use of the pouch. Stand-up pouches can be used for dry goods, liquids, powders, or even frozen products, so the choice of materials and closure should suit the product's characteristics.

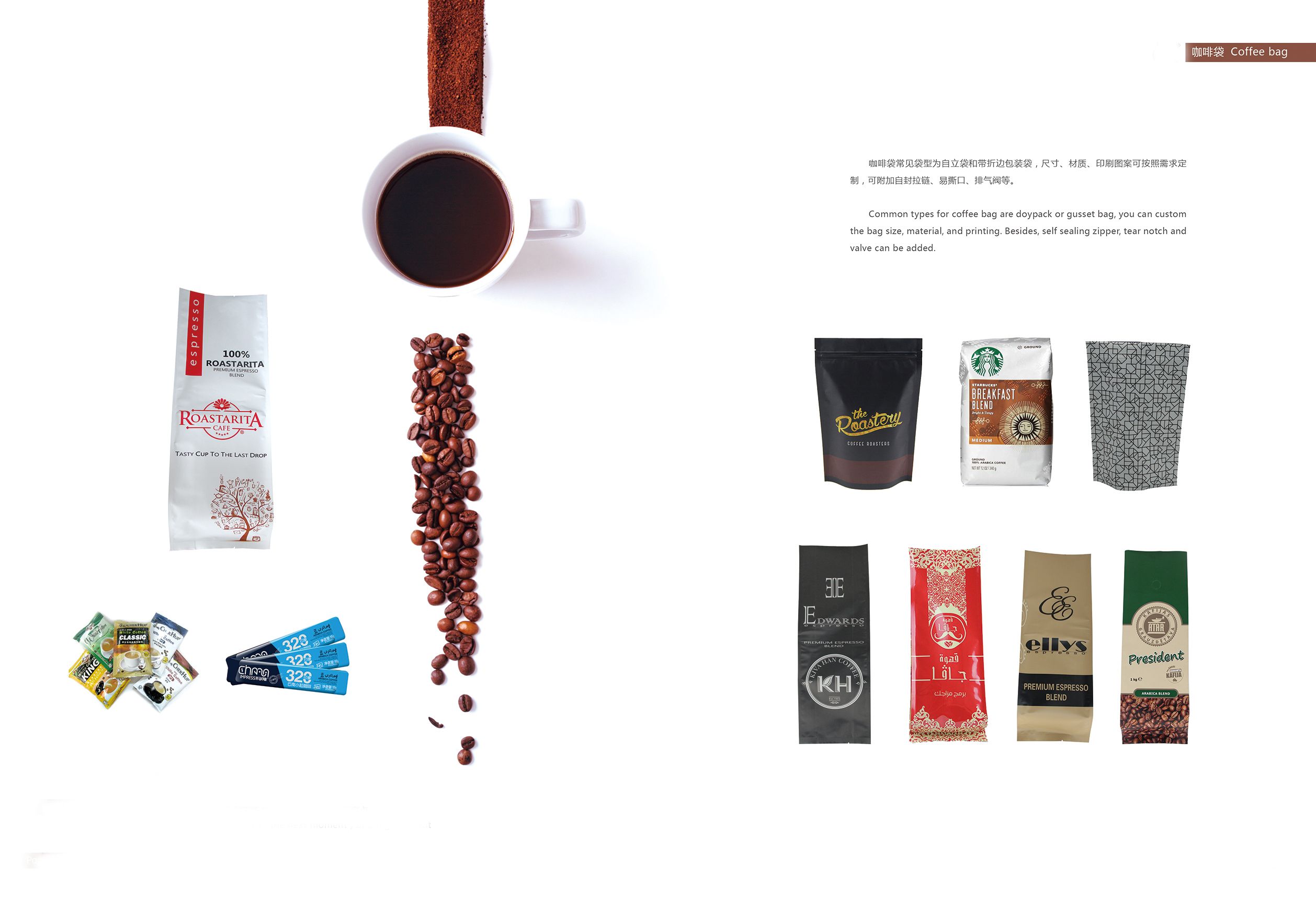

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

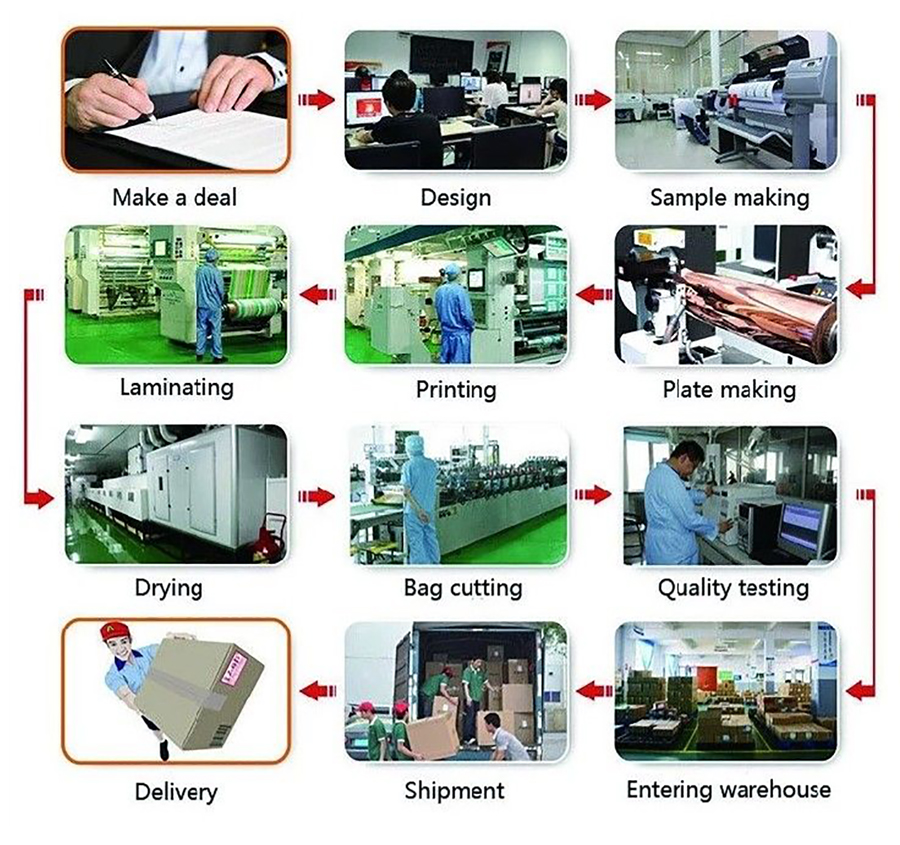

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.