Products

Custom Snack Nuts Peanut Packaging Bags Food Packaging For 250g 500g Nuts

1. Material Selection:

Barrier Films: Nuts are sensitive to moisture and oxygen, so barrier films like metallized films or laminated materials with multiple layers are commonly used to create a barrier against these elements.

Kraft Paper: Some nut packaging bags use Kraft paper as an outer layer for a natural and rustic appearance. However, these bags often have an inner barrier layer to protect the nuts from moisture and oil migration.

2. Size and Capacity:

Determine the appropriate bag size and capacity based on the quantity of nuts you want to package. Smaller bags are suitable for snack-sized portions, while larger bags are used for bulk packaging.

3. Sealing and Closure Options:

Zipper Seals: Resealable bags with zipper seals allow consumers to easily open and close the bag, keeping the nuts fresh between servings.

Heat Seals: Many bags have heat-sealed tops, providing an airtight and tamper-evident seal.

4. Valves:

If you're packaging freshly roasted nuts, consider using one-way degassing valves. These valves release gas produced by the nuts while preventing oxygen from entering the bag, preserving freshness.

5. Clear Windows or Panels:

If you want consumers to see the nuts inside, consider incorporating clear windows or panels into the bag design. This provides a visual showcase of the product.

6. Printing and Customization:

Customize the bag with vibrant graphics, branding, nutritional information, and allergen declarations. High-quality printing can help your product stand out on store shelves.

7. Stand-Up Design:

A stand-up pouch design with a gusseted bottom allows the bag to stand upright on store shelves, enhancing visibility and attractiveness.

8. Environmental Considerations:

Consider using eco-friendly packaging materials, such as recyclable or compostable films, to align with sustainability goals.

9. Multiple Sizes:

Offer various package sizes to cater to different customer preferences, from single-serving snack packs to family-sized bags.

10. UV Protection:

If your nuts are susceptible to UV light degradation, choose packaging with UV-blocking properties to maintain product quality.

11. Aroma and Flavor Retention:

Ensure that the packaging material chosen can preserve the aroma and flavor of the nuts, as these qualities are crucial for nut products.

12. Regulatory Compliance:

Ensure that your packaging complies with food safety and labeling regulations in your region. Nutritional facts, ingredient lists, and allergy information must be clearly displayed.

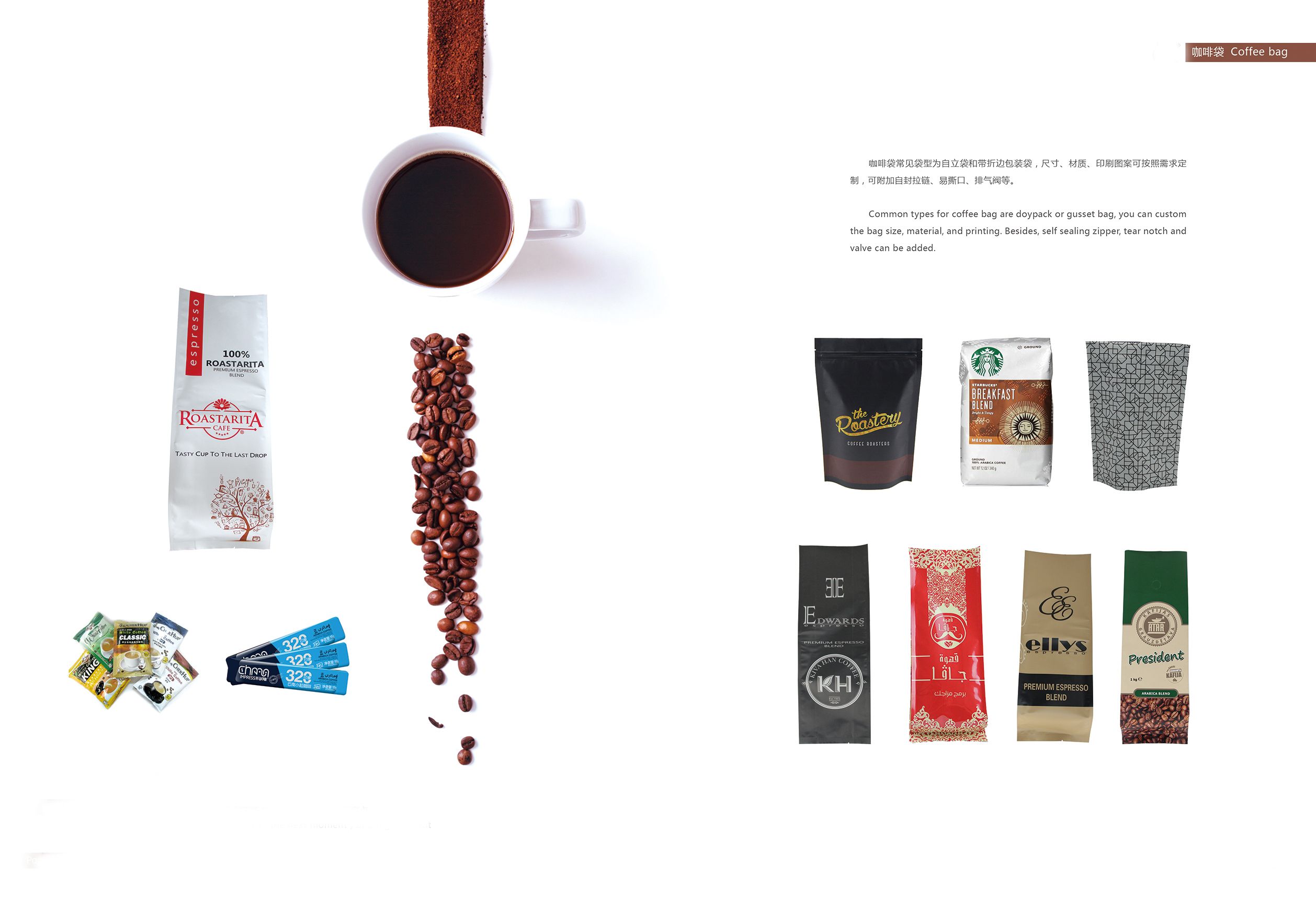

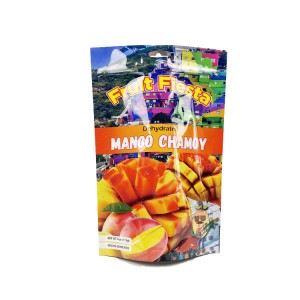

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

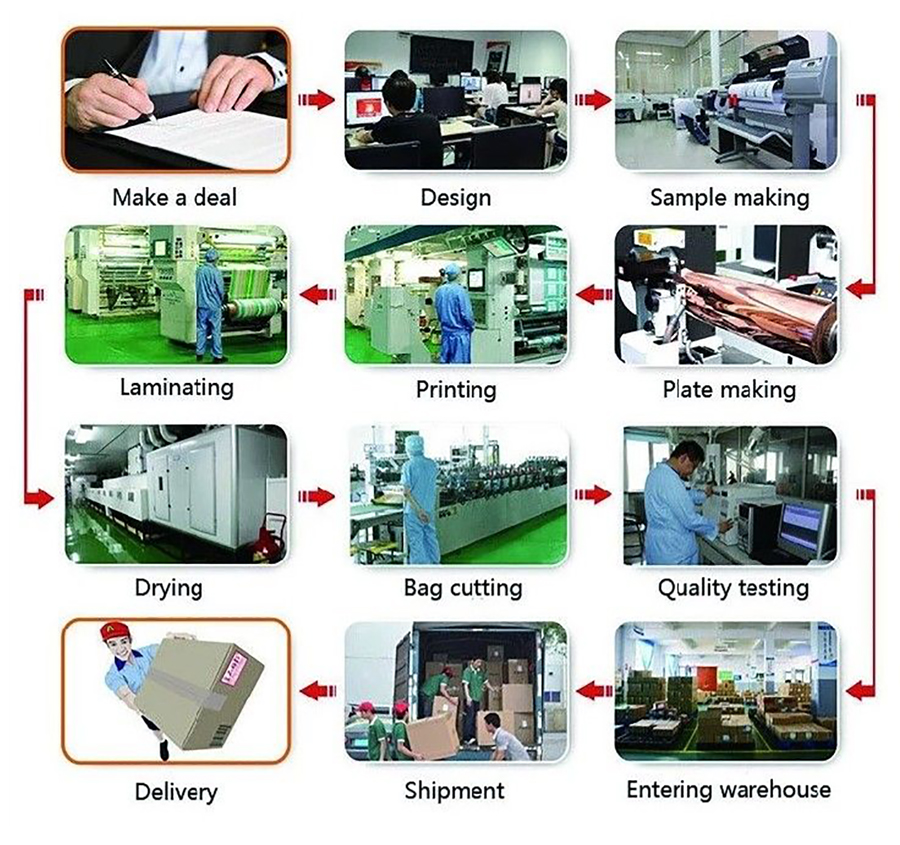

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.