Products

Laminated Waterproof Kraft Paper Bags Customized Brown and White Kraft Paper Bags With Window

Lamination: A lamination layer is added to the Kraft paper to make it waterproof and more resistant to moisture, grease, and oil. The lamination layer is often made of materials like polyethylene (PE) or polypropylene (PP).

Water Resistance: The lamination provides a high level of water resistance, making these bags suitable for products that need protection from humidity or wet conditions. This feature helps maintain the integrity of the packaged items.

Customization: Laminated waterproof Kraft paper bags can be customized in terms of size, shape, printing, and branding. Businesses can add their logos, product information, and designs to enhance the packaging's visual appeal.

Closure Options: These bags may feature different closure options, such as heat-sealed tops, resealable zippers, tin-tie closures, or fold-over tops with adhesive strips.

Tear Resistance: The lamination layer enhances the tear resistance of the bags, ensuring that they can withstand handling and transportation without easily tearing.

Eco-Friendly Options: Some manufacturers offer laminated Kraft paper bags with eco-friendly lamination materials, making them more sustainable and aligning with green packaging trends.

Versatility: Laminated waterproof Kraft paper bags are versatile and can be used for various products, including dry food items, pet food, coffee beans, grains, chemicals, and more.

Recyclability: While the lamination layer makes recycling more challenging, some laminated Kraft paper bags are designed to be partially recyclable or can be recycled in facilities equipped to handle mixed-material packaging.

Brand Promotion: Custom printing and branding options allow businesses to effectively promote their products and communicate their commitment to quality and sustainability.

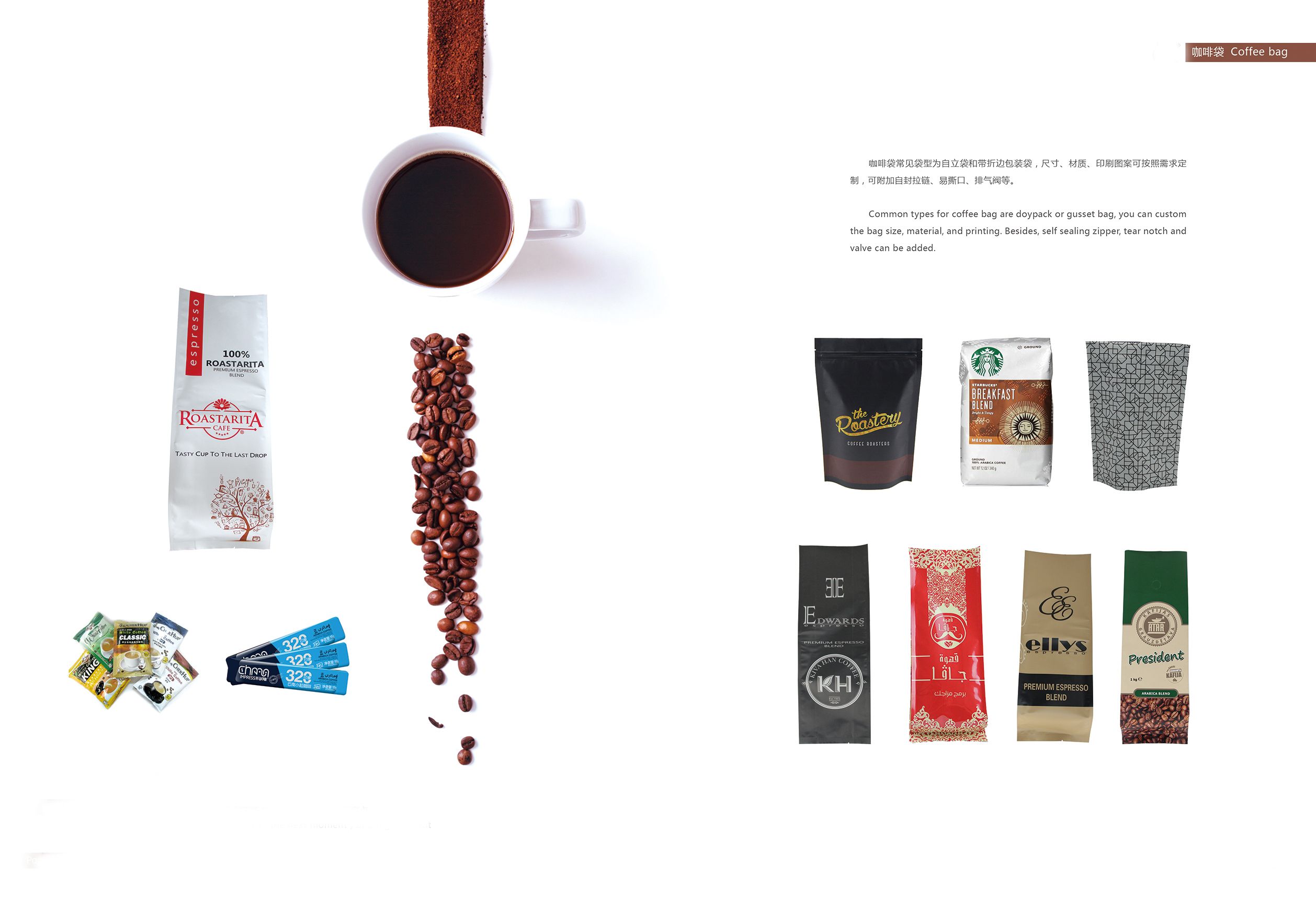

We also have the following range of bags for your reference.

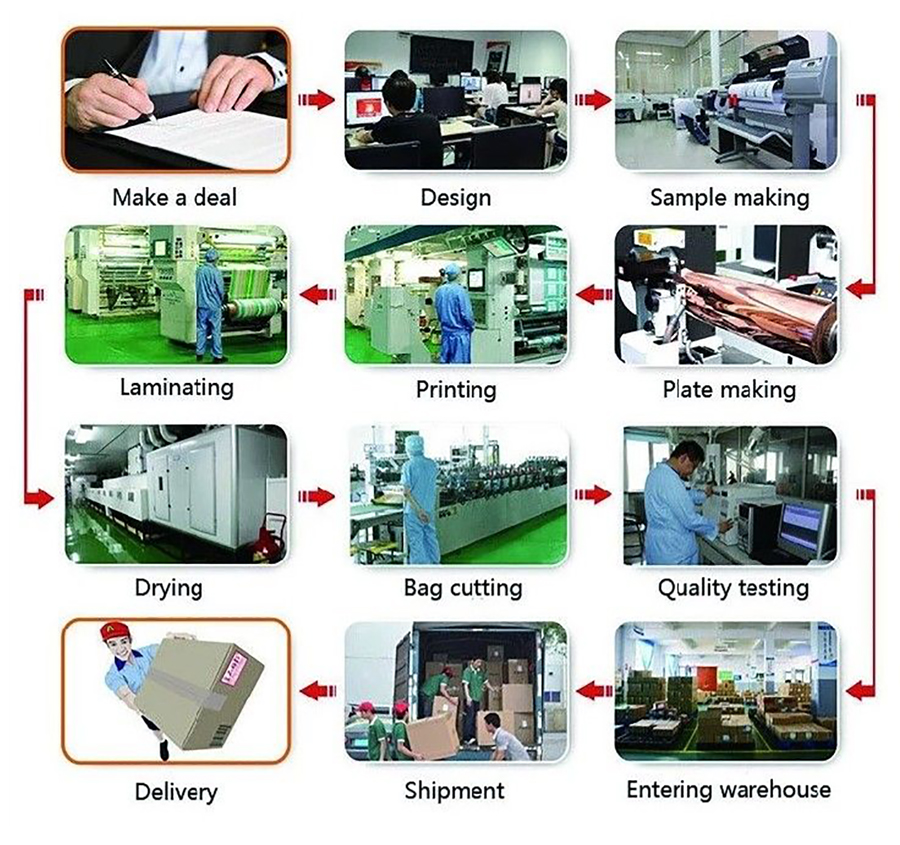

We are a professional packing factory, with 7 1200 square meter workshop and more than 100 skilled workers ,and we can make all kinds of food bags, clothing bags,roll film, paper bags and paper boxes, etc.

Yes, we accept OEM works. We can custom the bags according to your detail requirements, like bag type, size, material, thickness, printing and quantity, all can be customized based on your needs.

Kraft paper bags are generally divided into single-layer kraft paper bags and composite multi-layer kraft paper bags. Single-layer kraft paper bags are more widely used in shopping bags, bread, popcorn and other snacks. And kraft paper bags with multi-layer composite materials are mostly made of kraft paper and PE. If you want to make the bag stronger, you can choose BOPP on the surface and composite aluminum plating in the middle, so that the bag looks very high-grade. At the same time, kraft paper is more environmentally friendly, and more and more customers prefer kraft paper bags.

We can make many different kind of bags, like flat bag, stand up bag, side gusset bag, flat bottom bag, zipper bag, foil bag, paper bag, child resistance bag, matt surface, glossy surface, spot UV printing, and bags with hang hole, handle, window, valve, etc.

In order to give you a price, we need to know the exact bag type(flat zipper bag, stand up bag, side gusset bag, flat bottom bag, roll film), material(plastic or paper, matt, glossy, or spot UV surface, with foil or not, with window or not), size, thickness, printing and quantity. While if you cant tell exactly, just tell me what will you pack by the bags, then i can suggest.

Our MOQ for ready to ship bags is 100 pcs, while MOQ for custom bags is from 5000-50,000 pcs according to the bag size and type.