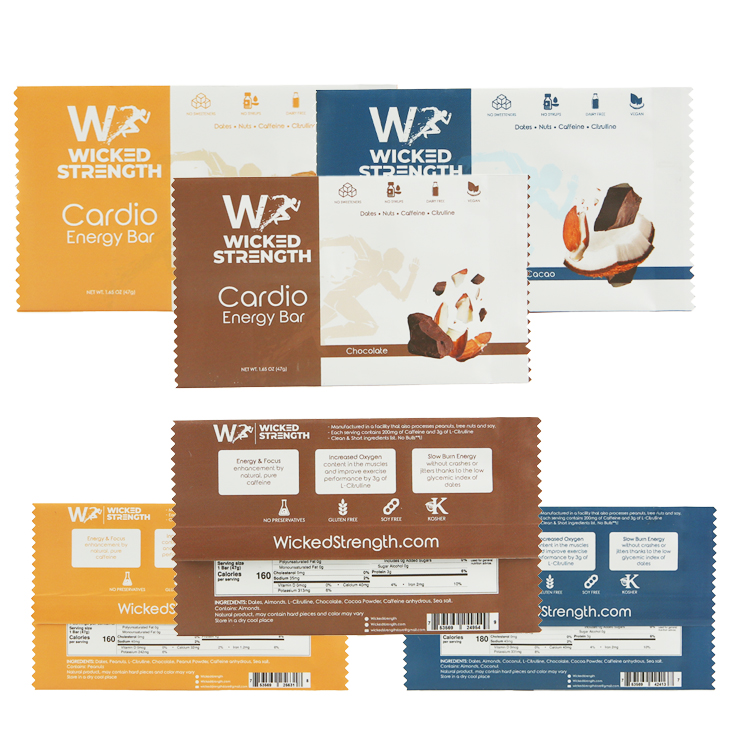

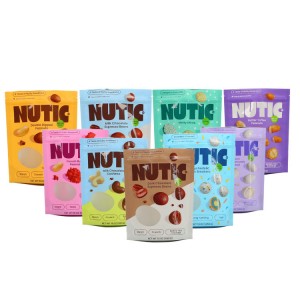

Products

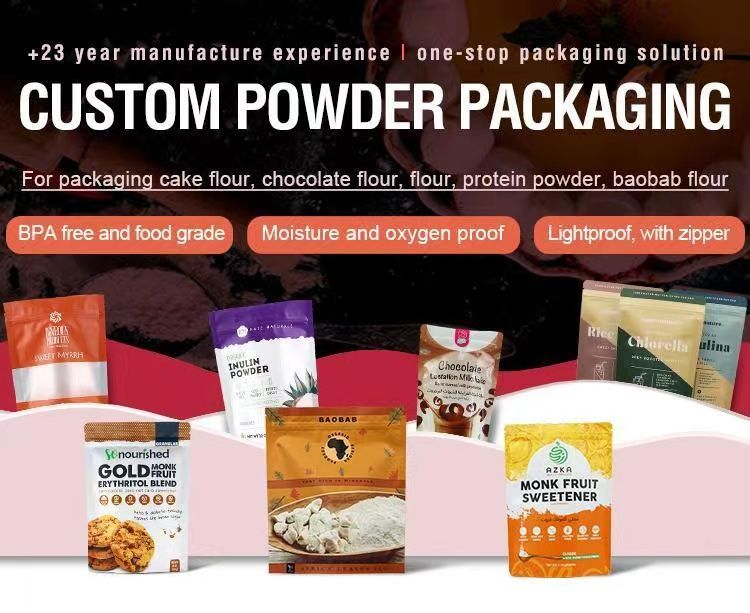

Custom Three Side Food Pouch Aluminum Foil Mylar Bag

Structure:A three-side-sealed pouch is typically made from layers of different materials, including aluminum foil or mylar for barrier properties, along with other layers like plastic films. These layers are designed to provide protection against moisture, oxygen, light, and external contaminants.

Sealing:As the name suggests, these pouches are sealed on three sides, leaving one side open for filling the food product. After filling, the open side is sealed using heat or other sealing methods, creating an airtight and tamper-evident closure.

Packaging Variety:Three-side-sealed pouches are versatile and come in various sizes and shapes, making them suitable for packaging a wide range of food products, including snacks, dried fruits, nuts, coffee, tea, spices, and more.

Customization:Manufacturers can customize these pouches with printed branding, labels, and designs to enhance product visibility and branding.

Convenience:The pouches can be designed with easy tear notches or resealable zippers for consumer convenience.

Shelf Life:Due to their barrier properties, three-side-sealed aluminum foil or mylar pouches help extend the shelf life of the enclosed food products, ensuring they remain fresh and flavorful.

Portability:These pouches are lightweight and portable, making them suitable for on-the-go snacks and single-serving portions.

Cost-Effective:Three-side-sealed pouches are often more cost-effective than other packaging options, making them an attractive choice for both manufacturers and consumers.

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

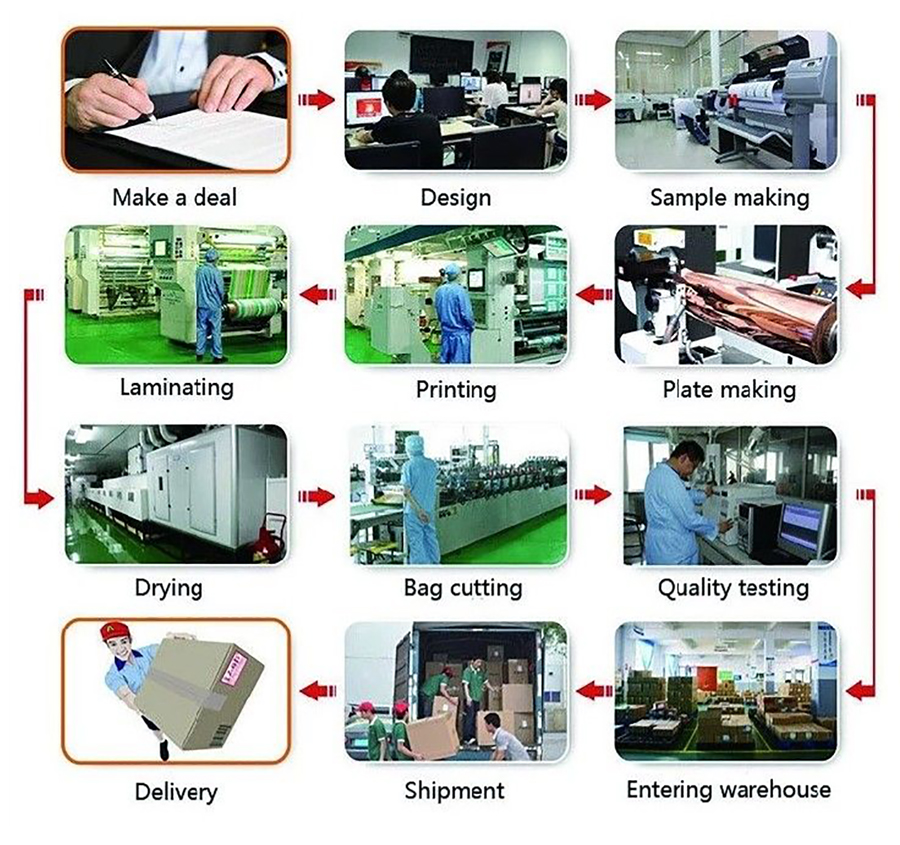

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.