Products

Custom printed resealable coconut chips snack food plastic packaging bag

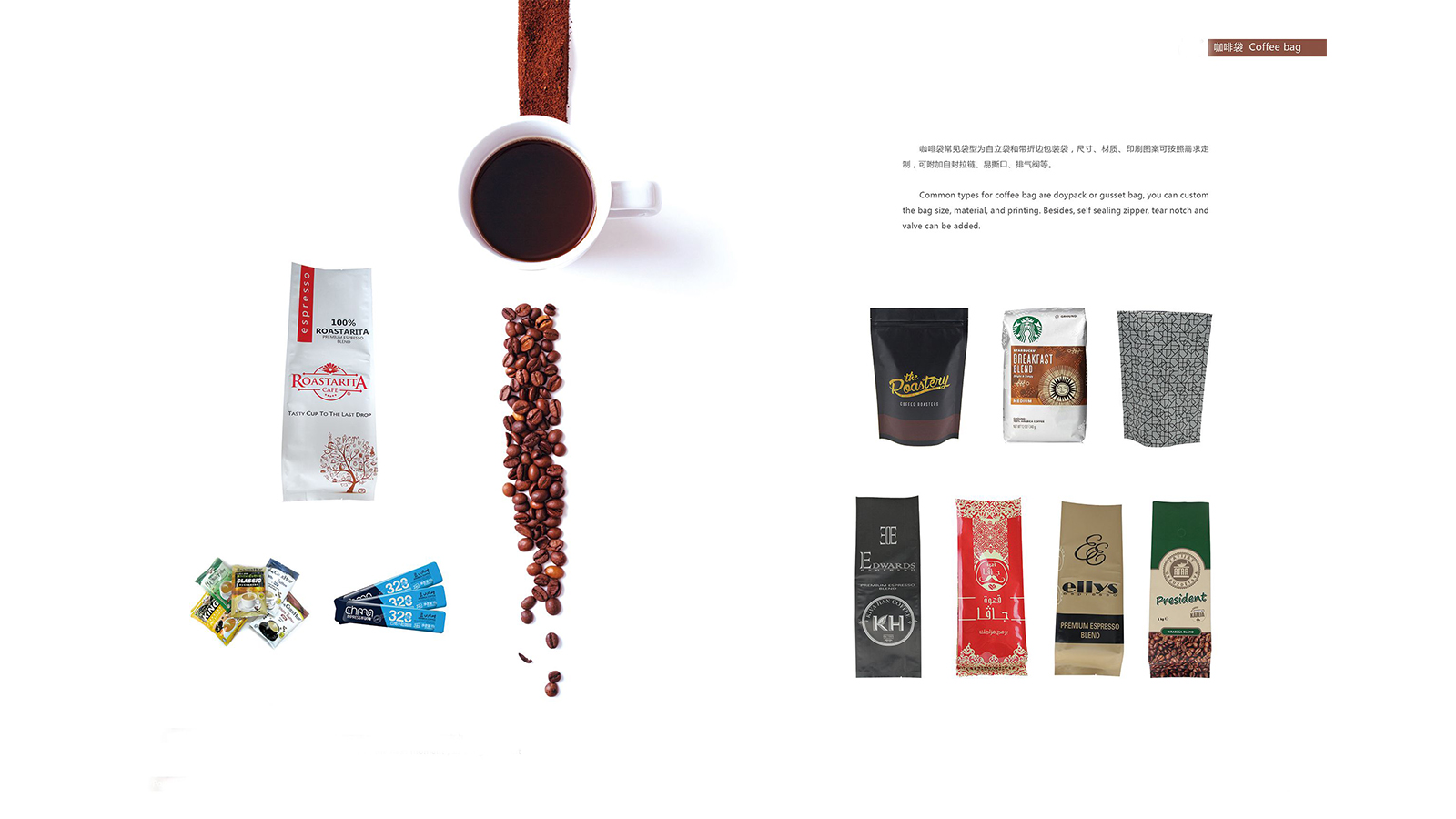

Coconut Chips Snack Food Plastic Packaging Bag

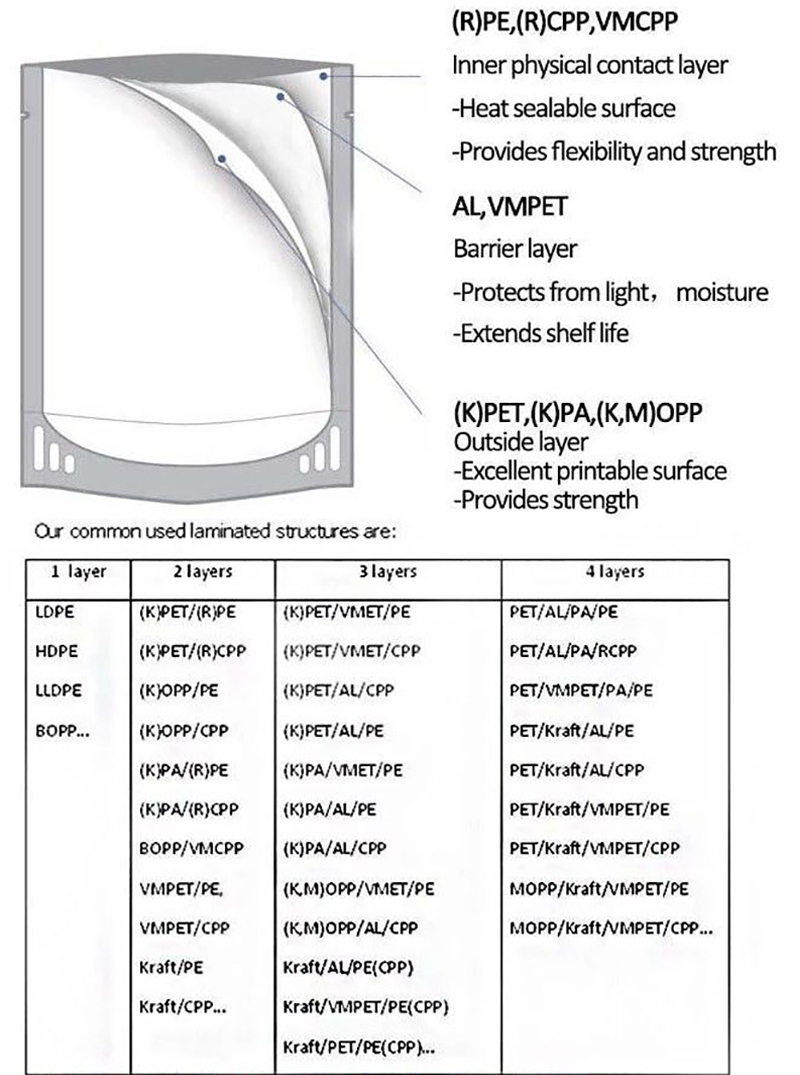

Bag Material:These bags are usually made from food-grade plastic materials, such as polyethylene (PE) or polypropylene (PP). These plastics are safe for food contact and offer excellent moisture and oxygen barrier properties to keep the coconut chips fresh.

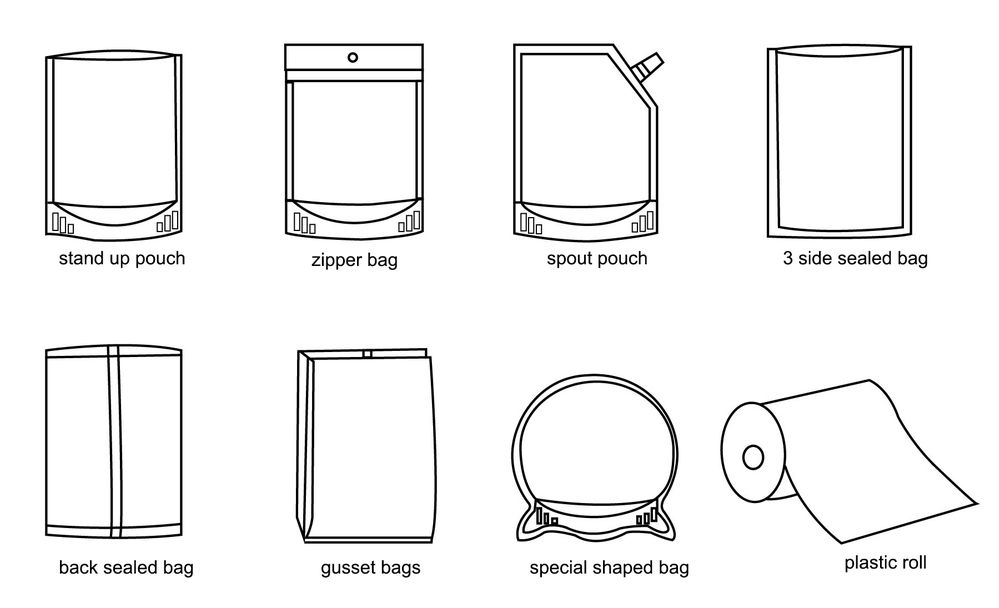

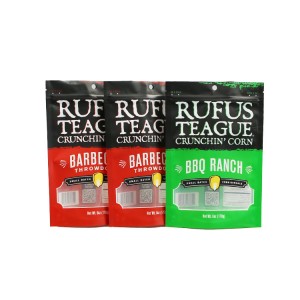

Bag Design:The bags are designed to be flat or stand-up, depending on the packaging requirements and branding preferences. Stand-up bags have a gusseted bottom that allows them to stand upright on store shelves, making them visually appealing.

Closure Mechanism:The bags often feature a resealable closure mechanism, such as a ziplock or slider zipper. This allows consumers to open and close the bag multiple times, keeping the coconut chips fresh between servings.

Size and Capacity:Coconut chip bags come in various sizes and capacities, from small single-serving pouches to larger family-sized bags. The choice of size depends on the product's intended use and the target market.

Labeling and Branding:The front surface of the bag is typically used for branding and product information. This includes the brand name, product name ("Coconut Chips"), weight or volume, nutritional facts, ingredients list, allergen information, and any other required labeling information.

Graphics and Design:Manufacturers often use attractive graphics, colors, and images on the packaging to make the product visually appealing to consumers and convey the product's flavor or key attributes.

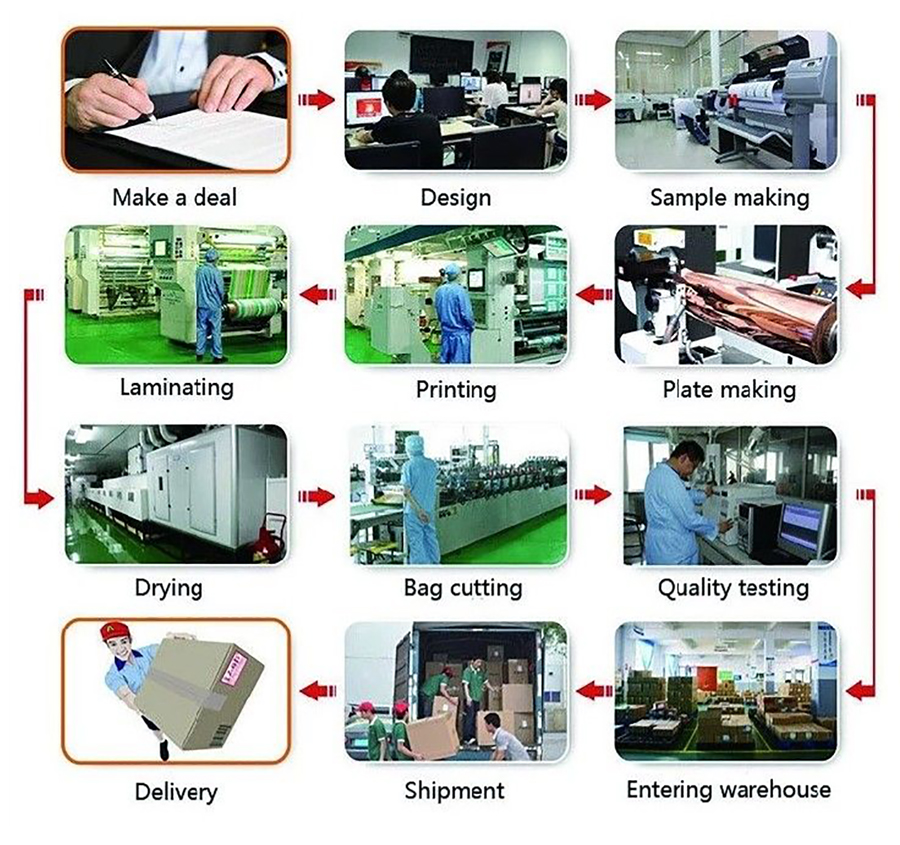

Production and Filling:Coconut chips are filled into the bags using automated filling equipment. Quality control measures are taken to ensure that the product is of high quality and free from foreign contaminants.

Sealing:The bags are sealed, often using heat sealing equipment, to ensure they are tamper-evident and airtight.

Quality Assurance:Prior to packaging, coconut chips may undergo quality assurance checks to meet the desired quality standards and safety requirements.

Distribution:Once packaged, the coconut chips bags are ready for distribution to retailers or consumers.

We also have the following range of bags for your reference.

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.