Products

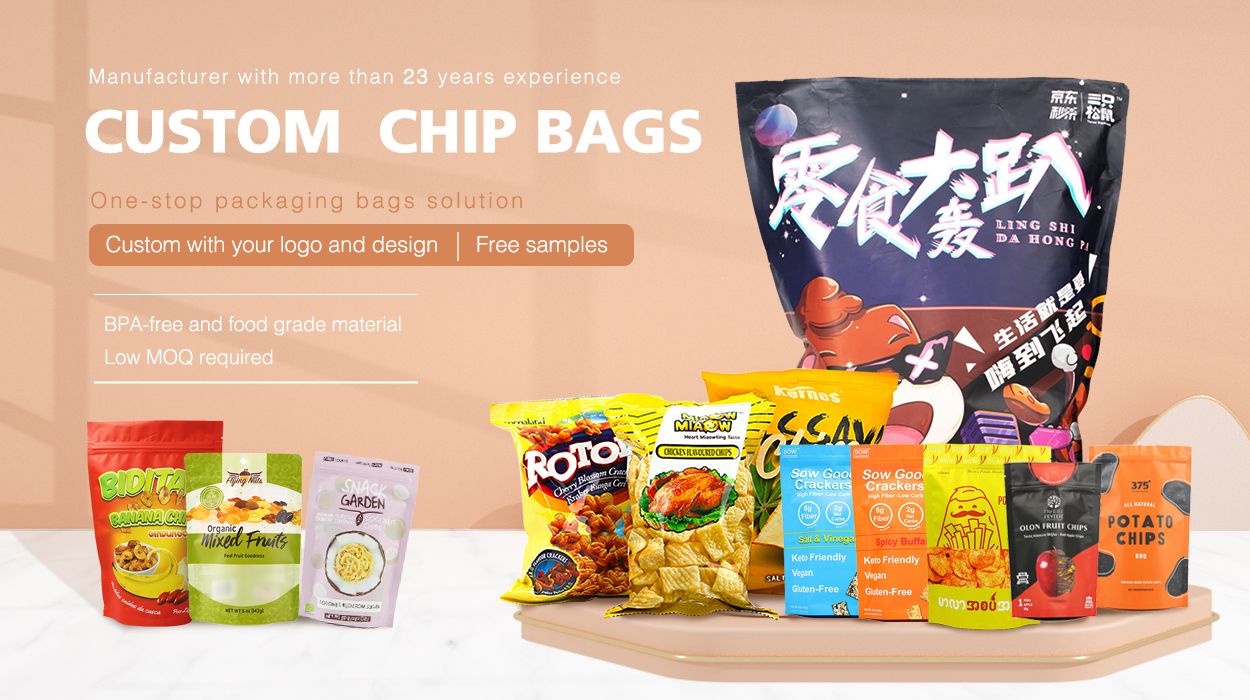

80G Chips Bags Manufacturer Custom Chips Bags

80G Chips Bags Manufacturer Custom Chips Bags

Materials: Chips bags are typically made from materials like polyethylene (PE), metallized films, polypropylene (PP), or laminated materials. The choice of material depends on factors such as product freshness, shelf life, and branding.

Size and Capacity: Chips bags come in various sizes, ranging from small single-serving bags to large family-sized packages. The size and capacity of the bag should match the product's intended portion size.

Design and Graphics: Eye-catching packaging design and graphics are essential to attract consumers. Custom printing allows brands to add logos, branding elements, product images, and promotional messages to the bags.

Closure Types: Common closure options for chips bags include heat-sealed tops, resealable zippers, or adhesive strips. Resealable features help keep snacks fresh after the initial opening.

Window Features: Some chips bags have clear windows or transparent panels that allow consumers to see the contents inside. This can be particularly appealing for showcasing the product's quality and appearance.

Barrier Properties: Chips bags often include inner layers or coatings to provide barrier properties, such as protection against moisture, oxygen, and light, which helps maintain the product's freshness.

Tear Notch: A tear-notch or easy-open feature is often included for user convenience when opening the bag.

Environmentally Friendly Options: Some manufacturers offer chips bags made from eco-friendly materials, including recyclable or biodegradable options, to align with sustainability goals.

Customization: Brands can customize chips bags in terms of size, shape, printing, and branding to create a unique and memorable packaging solution.

Promotional Varieties: Special promotional and seasonal packaging for chips are common, featuring limited-time designs and tie-ins with specific events or holidays.

Regulatory Compliance: Ensure that the packaging complies with relevant food safety and labeling regulations, including allergen information, nutritional facts, and ingredient lists.

Packaging Formats: In addition to traditional pillow-style bags, chips are often packaged in stand-up pouches, gusseted bags, or specialty shapes that help with shelf visibility and display.

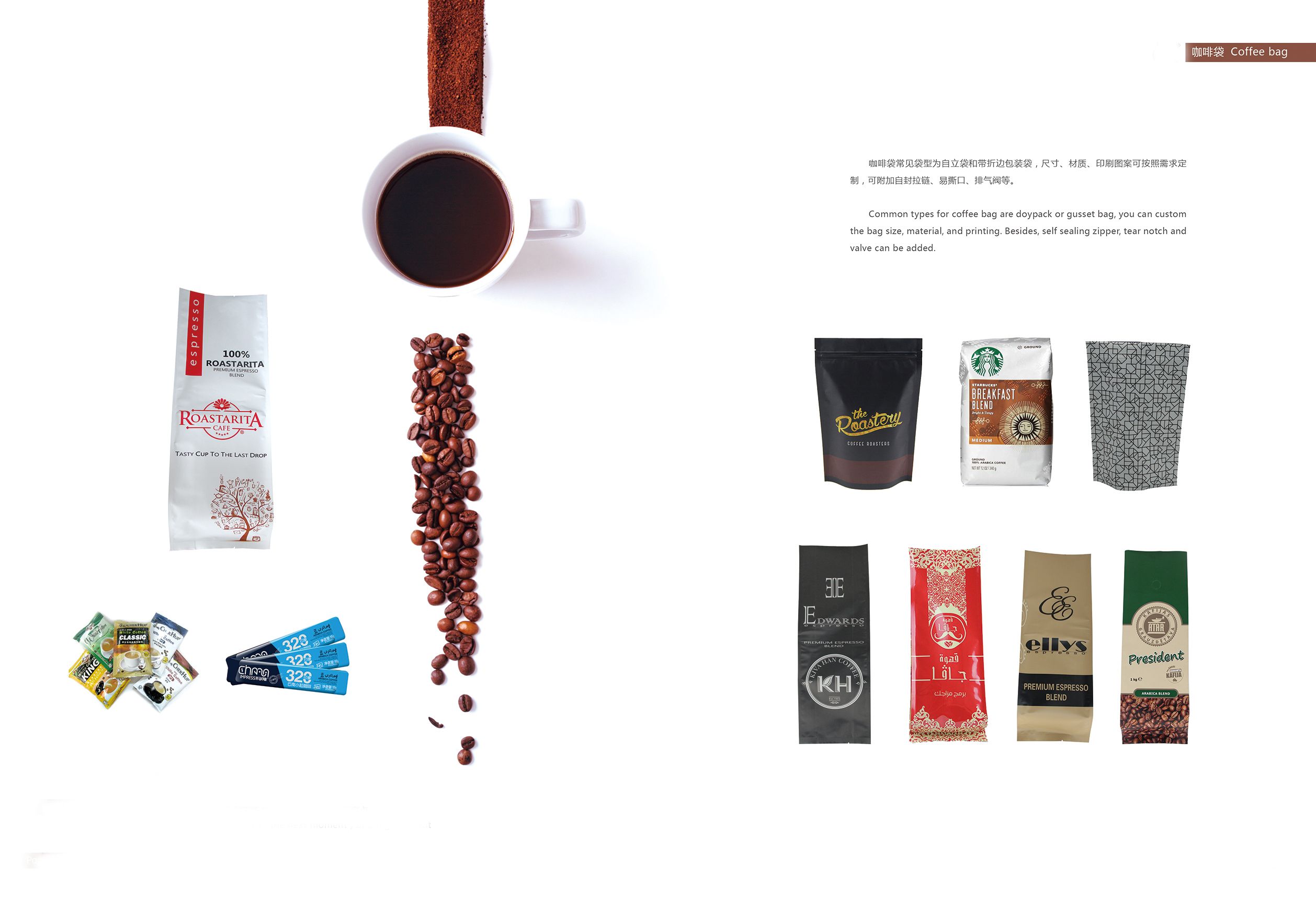

We also have the following range of bags for your reference.

A: Our factory MOQ is a roll of cloth, it’s 6000m long, about 6561 yard. So it depend on your bag size, you can let our sales figure it for you.

A: The production time is about 18-22 days.

A: Yes, but we don’t suggest make a sample, the model cost is too expensive.

A: Our designer can make your design on our model, we will confirm with you can produce it according to the design.