Products

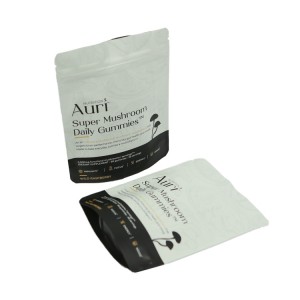

3.5g Mylar Bag Child Resistance Bag Cannabis Bag

For fresh foods such as meat, seafood and various vegetables and fruits, the key to their preservation lies in controlling the entry and exit of oxygen and moisture. Polyethylene (PE) cling film is a common choice. It can effectively block oxygen, slow down the oxidation rate of fresh food and prevent it from spoiling too quickly. At the same time, it can also retain moisture moderately, preventing fresh produce from losing its tender texture due to dehydration. For some high-quality fresh produce, PET/PE composite materials are more suitable. The PET layer offers excellent mechanical strength and barrier performance, capable of withstanding external impacts and the penetration of oxygen and moisture. The PE layer ensures the flexibility and heat-sealing property of the bag, making the packaging process more convenient and efficient. Aluminum foil is also a good choice for cooked food and meat that need to be vacuum-preserved. It not only has good mechanical properties, but also can preserve fragrance and freshness. The application of these materials creates a relatively stable internal environment for fresh food, extends their shelf life, enables consumers to purchase fresh products as fresh as new, and ensures the safety of consumption.

Dried goods, such as beans and nuts, have extremely high requirements for moisture resistance due to their low water content. Aluminum foil composite bags perform exceptionally well in this aspect. Aluminum foil has excellent barrier properties and can completely block moisture, oxygen and light. The dried goods are packed in aluminum foil composite bags and can be stored for a long time without worrying about moisture, mold, oxidation, rancidity or pest infestation. Even in a humid environment, aluminum foil composite bags safeguard the quality of dried goods, allowing their nutritional components and taste to be fully preserved, enabling consumers to enjoy the original flavor of the dried goods when consuming them. Even as time passes quietly, the practical goods can still hold fast to their original intentions.

Baked goods, such as bread, cakes, biscuits, etc., have their unique packaging requirements. This type of food needs to maintain its crispy texture while preventing oil from seeping out. Packaging bags made of polypropylene (PP) or polyester (PET) can well meet these requirements. They are like two fine and tough filters. On the one hand, they can precisely prevent the "escape" of oil molecules, ensuring that the packaging appearance remains clean and new all the time and avoiding the impact on consumers' visual experience and purchasing desire due to oil leakage. On the other hand, it ingeniously retains a certain degree of breathability, just like opening up a "breathing channel" for baked goods, allowing water vapor to escape in an orderly manner, thereby effectively preventing the embarrassing situation of softening and losing the crispness due to the accumulation of water vapor. This ensures that when consumers open the package, they can still taste the wonderful texture of the baked goods just out of the oven.

The material of food packaging bags is closely related to the preservation and safety of food. As a food packaging bag manufacturer, it is our core task to deeply understand the characteristics of different foods and precisely match the appropriate packaging bag materials. Only in this way can reliable guarantees be provided for food during storage and transportation, allowing consumers to enjoy every delicacy with peace of mind, and also enabling the supply chain of the food industry to operate more stably and efficiently.