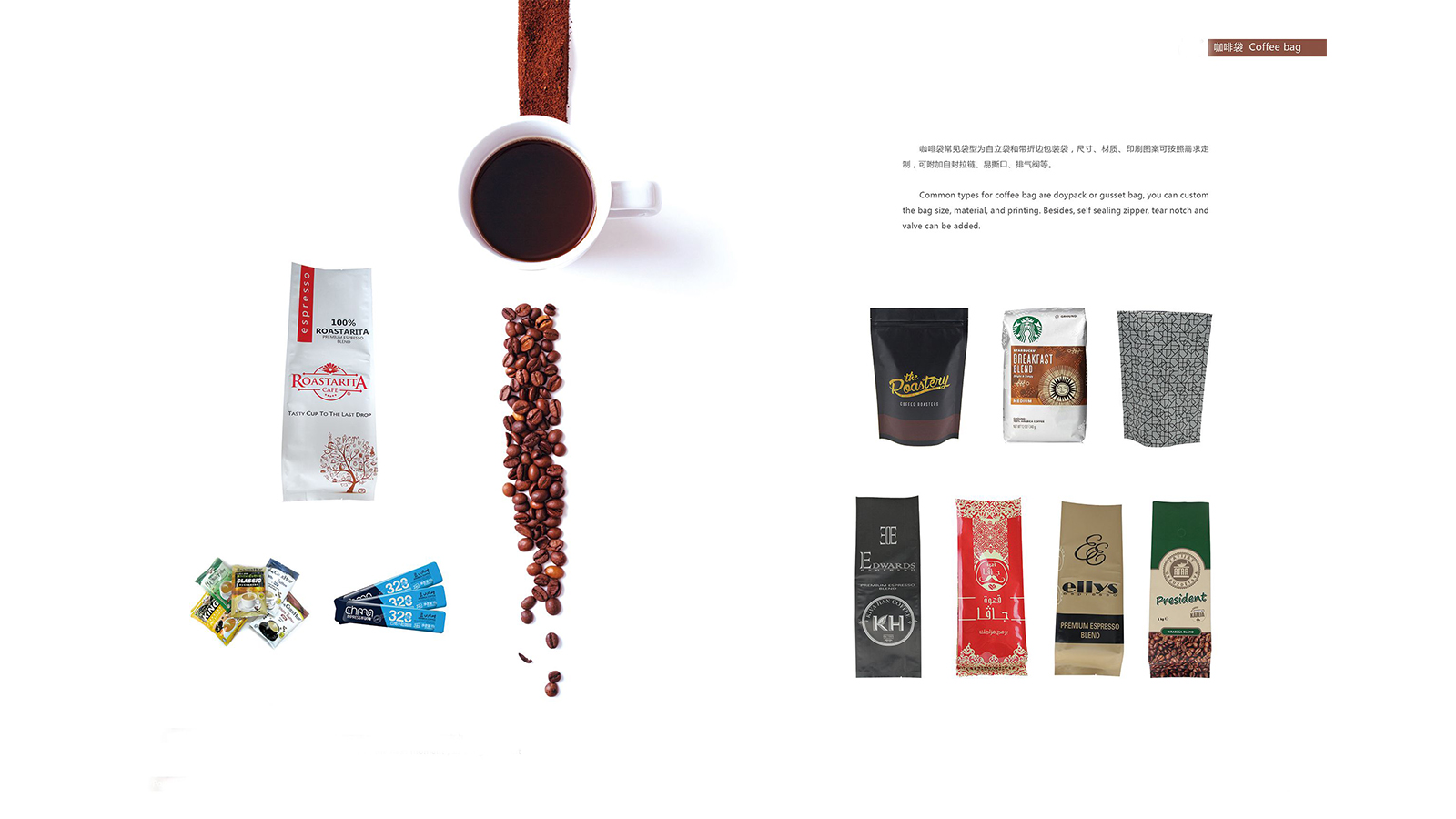

Products

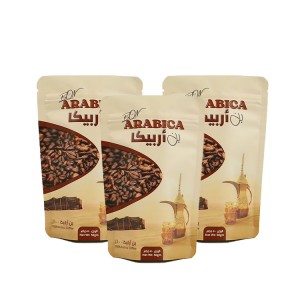

1lb Aluminum Foil Coffee Sachet Packaging Bags With Filter

1lb Aluminum Foil Coffee Bags

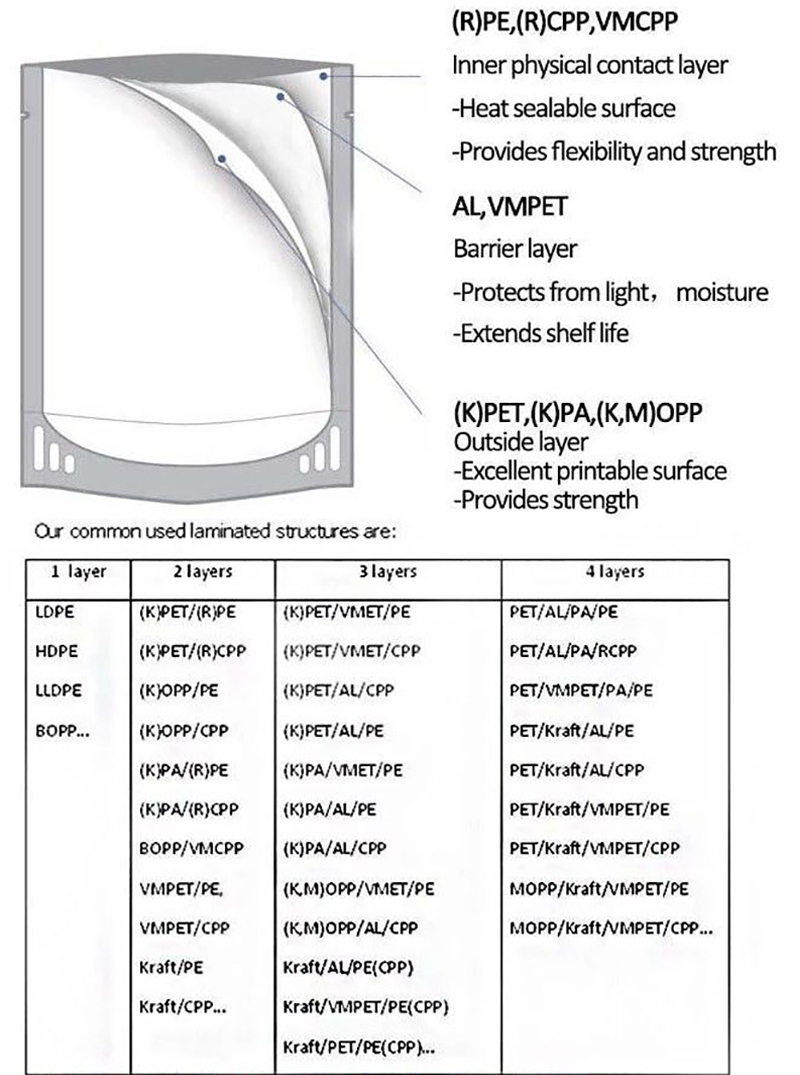

Material composition: Aluminum foil coffee bags are usually composed of several layers. Outer layer: This layer can be composed of printed paper or plastic film, providing space for branding, product information and eye-catching design. Aluminum foil layer: Aluminum foil layer acts as a barrier to light, moisture, oxygen and other environmental factors. It helps maintain the freshness of the coffee and prevents flavor loss and oxidation. Inner layer: The innermost layer is usually made of heat-sealable plastic or other material to ensure an airtight seal after the bag is closed.

Deaeration valve: Many aluminum foil coffee bags have a one-way deaeration valve. This valve allows gas, mainly carbon dioxide, to escape from the freshly roasted coffee beans without allowing outside air to enter. This is essential to maintain the flavor of the coffee and prevent the bag from cracking due to gas buildup.

Resealable zipper: To keep coffee fresh after opening the bag, aluminum foil coffee bags often come with resealable zippers. This feature allows consumers to easily open and reseal the bag between uses.

Size variations: These bags come in different sizes to hold different amounts of coffee, from single servings to larger bulk packing options.

Custom printing: Manufacturers can customize the brand, logo, product information and design elements on the outer layer of the packaging bag to make the product stand out on the store shelf.

Heat seal: Many aluminum foil coffee bags are designed to heat seal after filling to ensure a tight seal and maintain the freshness of the coffee.

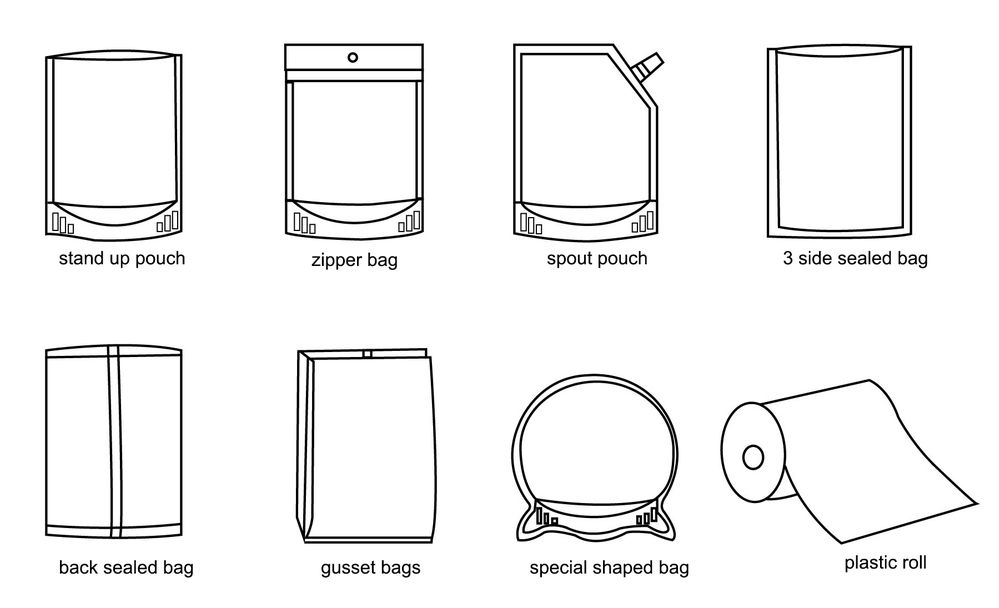

Standing pouch design: Aluminum foil coffee bags usually have standing pouch designs, which provide shelf stability and make the bag easy to display.

Tear notches: Some bags include tear notches or easy-to-open features for easy access to coffee without the need for scissors or other tools.

Environmental considerations: As sustainability becomes more important, some manufacturers offer aluminum foil coffee bags made from recyclable materials or with environmental certification.

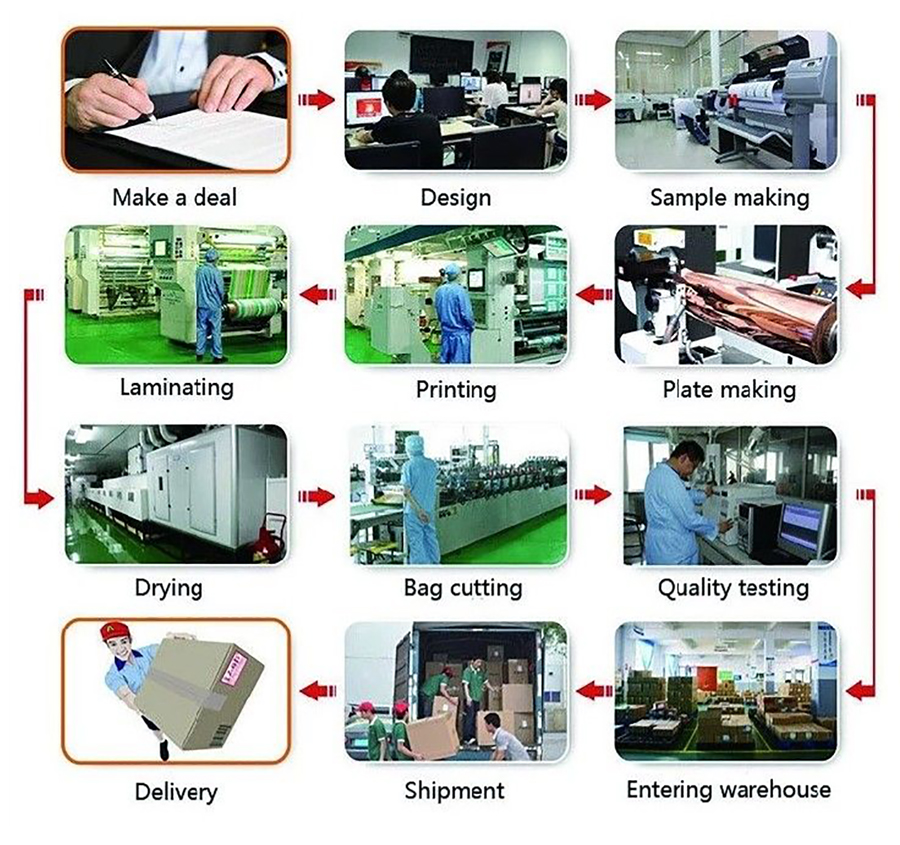

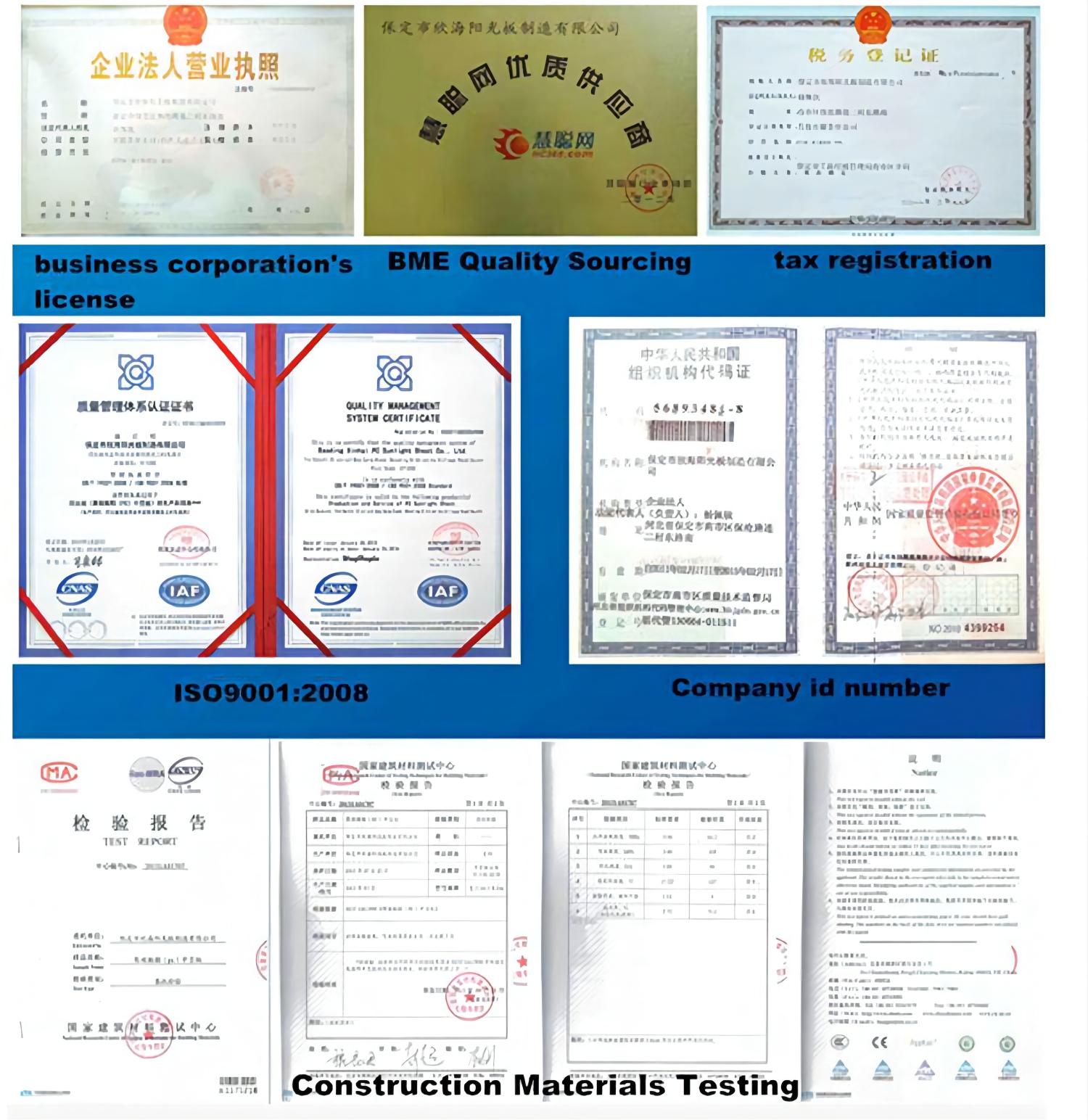

Quality control: Strict quality control measures should be taken during the production process to ensure that the bag effectively protects the coffee and maintains its quality.

We also have the following range of bags for your reference.

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.