Products

Custom Printing Resealable Plastic Food Seal Packaging Ziplock Foil Pouch 14g Zipper Smell Proof Cookie Mylar Bag With Logo

14g Zipper Smell Proof Cookie Mylar Bag With Logo

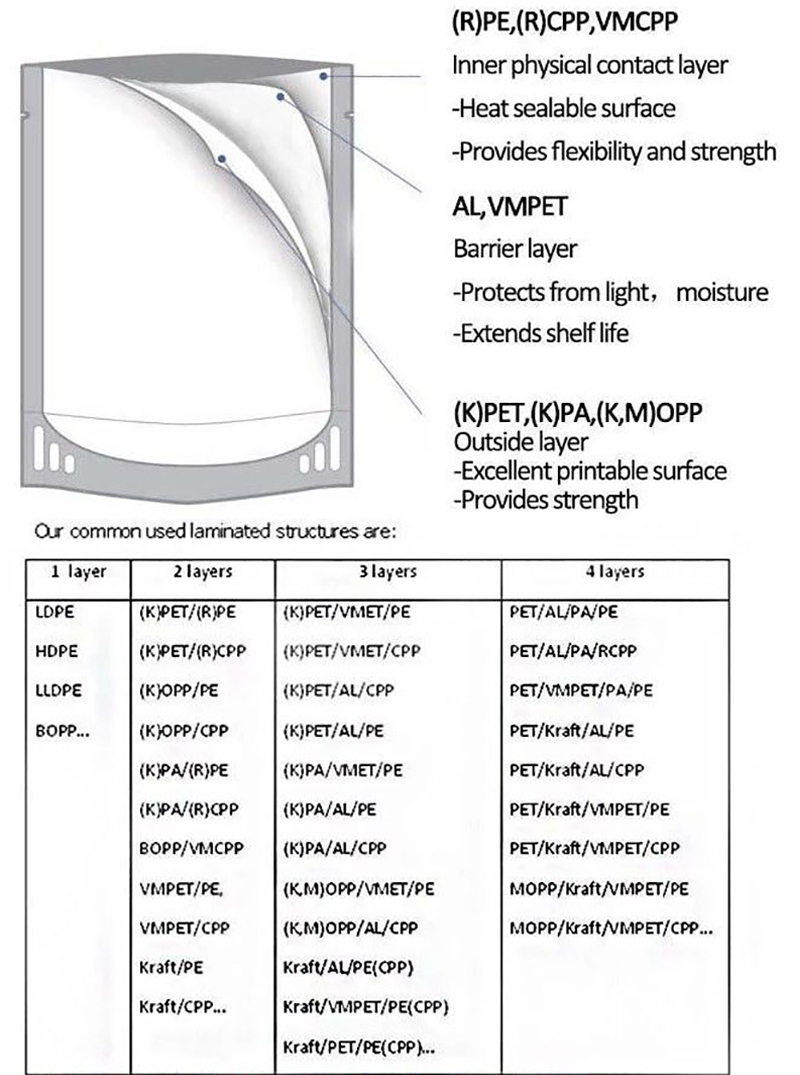

Material:Food seal packaging ziplock foil pouches are typically made from multiple layers of materials. These layers often include aluminum foil, which provides excellent barrier properties against moisture, oxygen, light, and contaminants. The inner layer is usually made of food-grade materials for safety and compatibility with various food items.

Ziplock Closure:These pouches are equipped with a ziplock or resealable closure mechanism. The ziplock feature allows consumers to open and reseal the pouch easily, helping to maintain the freshness of the enclosed food product and extend its shelf life.

Airtight Seal:The ziplock mechanism creates an airtight seal when properly closed. This seal helps prevent moisture and air from entering the pouch, which is crucial for preserving the quality and flavor of the food inside.

Barrier Properties:The aluminum foil layer in these pouches acts as a barrier to light, oxygen, and moisture, which are some of the main factors that can lead to food spoilage and degradation. This makes them suitable for packaging items like snacks, coffee, tea, dried fruits, nuts, and spices.

Customizable:Food seal packaging ziplock foil pouches are customizable in terms of size, shape, and design. Many manufacturers offer options for custom printing, allowing businesses to brand their products and add information like logos, product names, and nutritional information.

Heat Sealing:While the ziplock closure provides convenience for consumers, the pouches are also compatible with heat sealing machines. This option is commonly used in food manufacturing and packaging facilities for a more secure and tamper-evident seal.

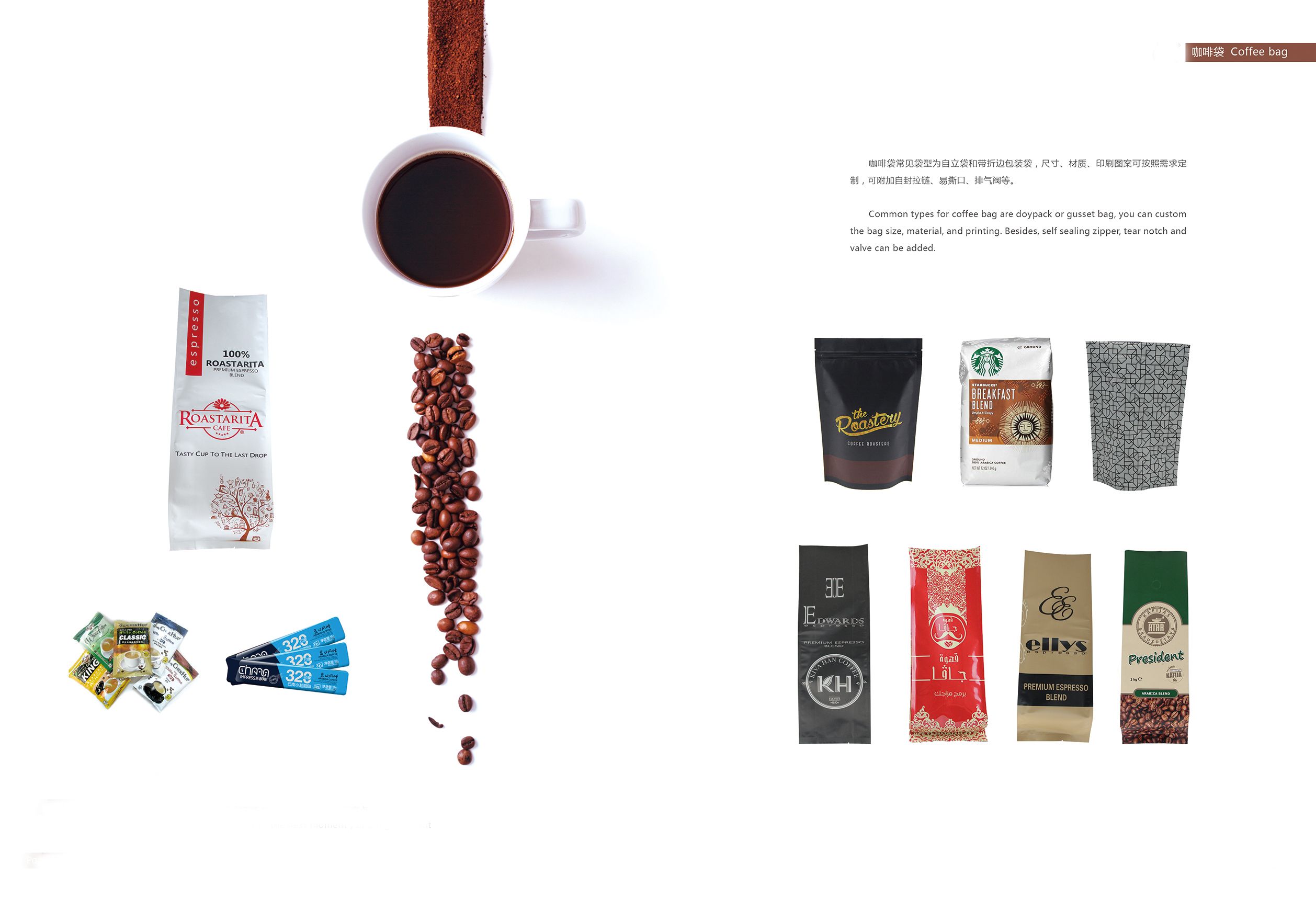

Stand-Up Pouches:Some ziplock foil pouches are designed with a gusseted bottom, allowing them to stand upright on store shelves. This feature is especially popular for packaging snacks, dried fruits, and other food products.

Eco-Friendly Options:In response to environmental concerns, some manufacturers offer eco-friendly variations of these pouches, which are made with recyclable or biodegradable materials.

We also have the following range of bags for your reference.

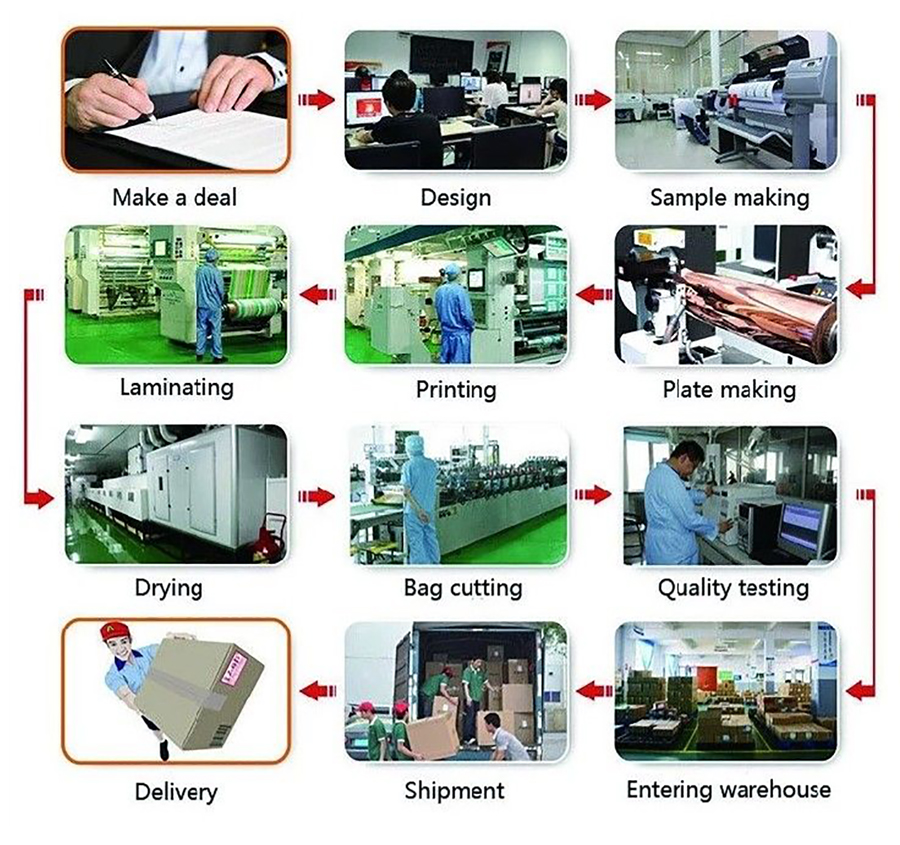

We are a professional packing factory, with 7 1200 square meter workshop and more than 100 skilled workers ,and we can make all kinds of cannabi bags,gummi bags, shaped bags, stand up zipper bags, flat bags, child-proof bags, etc.

Yes, we accept OEM works. We can custom the bags according to your detail requirements, like bag type, size, material, thickness, printing and quantity, all can be customized based on your needs.We have our own designers and we can provide you with free design services.

We can make many different kind of bags, like flat bag, stand up bag, stand up zipper bag,shaped bag, flat bag,child proof bag.

Our materials include MOPP, PET, laser film, soft touch film.Various types for you to choose from,matt surface, glossy surface, spot UV printing, and bags with hang hole, handle, window, easy tear notch etc.

In order to give you a price, we need to know the exact bag type(flat zipper bag, stand up zipper bag,shaped bag, child proof bag), material(Transparent or aluminized, matt, glossy, or spot UV surface, with foil or not, with window or not), size, thickness, printing and quantity. While if you cant tell exactly, just tell me what will you pack by the bags, then i can suggest.

Our MOQ for ready to ship bags is 100 pcs, while MOQ for custom bags is from 1,000-100,000 pcs according to the bag size and type.