Products

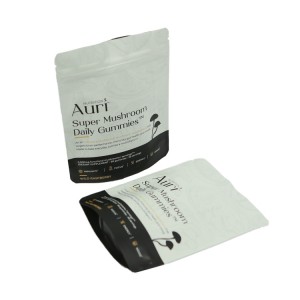

14g Darts Child Resistant Zipper Hand Rolling Mylar Bag

14g Darts Child Resistant Zipper Mylar Bag

Child containment: The main feature of these bags is the child containment mechanism. This often involves a zipper or sliding lock mechanism that requires a specific set of actions to open, making it difficult for young children to access the content.

Zipper design: Zippers used in child safety bags usually have special safety features, such as push-turn mechanism or squeezing-slide design. These mechanisms may require dexterity and strength that are beyond the abilities of most young children.

Adult Friendly access: Although children resist, these bags are designed to be easy for adults to open using prescribed methods. Clear instructions are usually provided on how to open the bag for adult users.

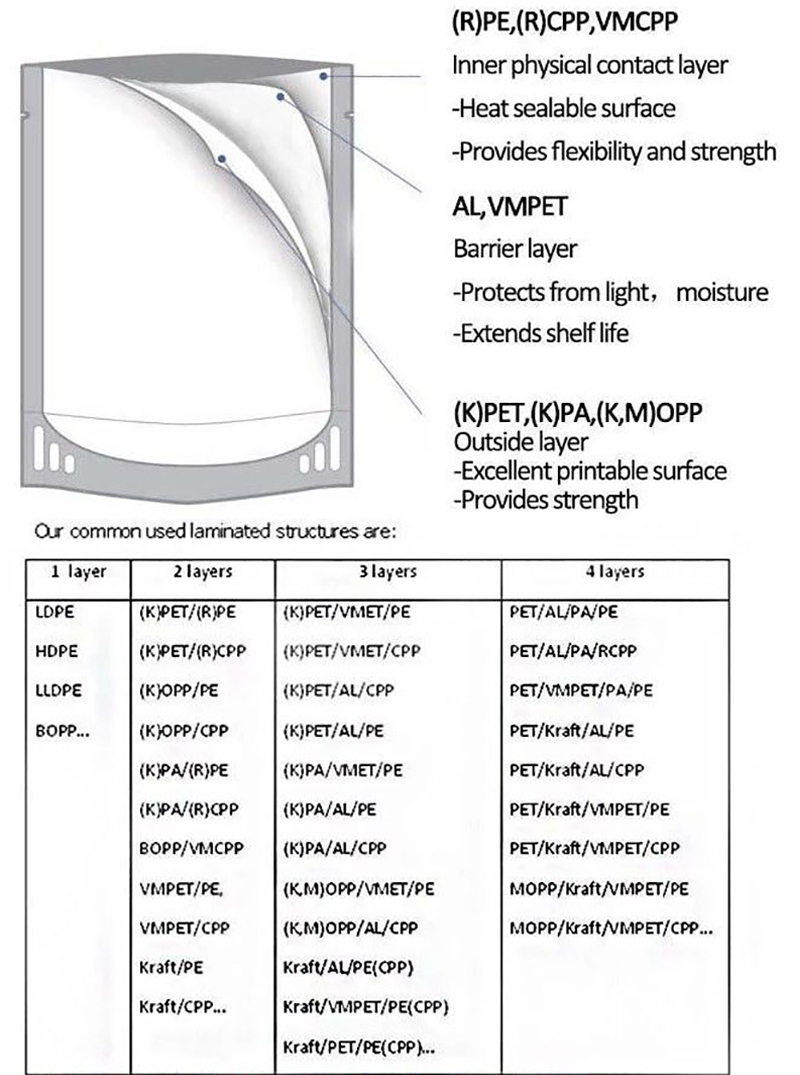

Materials: Children's zipper-proof flat bags can be made of a variety of materials, including plastic, mylar, or a combination of materials that provide a barrier against moisture, light, and odor. The choice of materials depends on the specific product being packaged and any regulatory requirements.

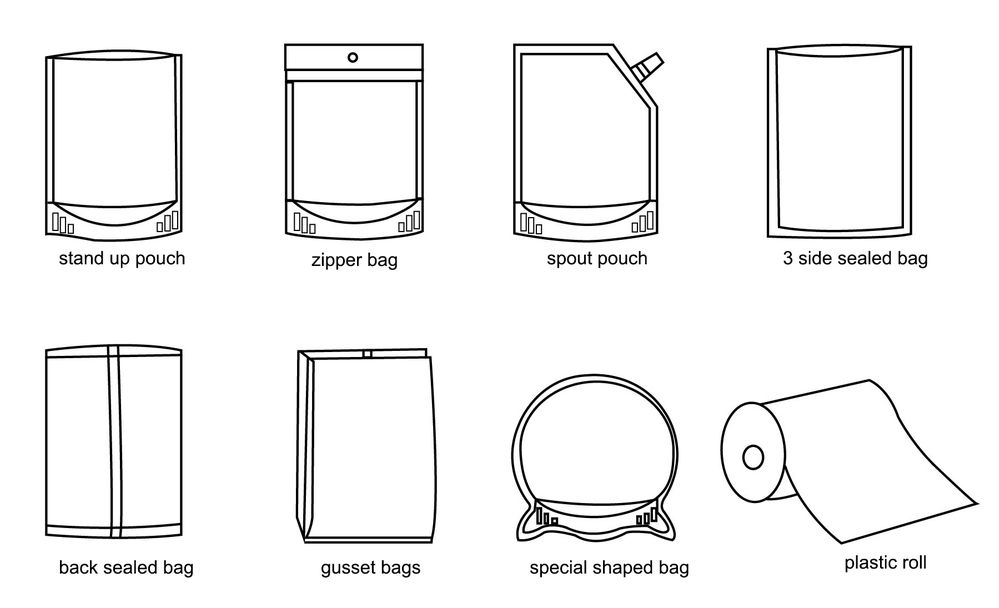

Sizes and styles: These bags come in a variety of sizes and styles to suit different products. They range from small bags to large bags, depending on your packaging needs.

Compliance: When using child-safe packaging, it is important to ensure that it complies with relevant regulations and standards, especially when you are packing medicines, cannabis or other controlled substances. Regulations may vary by region or country.

Customization: Choose to customize these bags with brand, product information and warning labels. Customization can help reinforce your brand image and provide consumers with important product information.

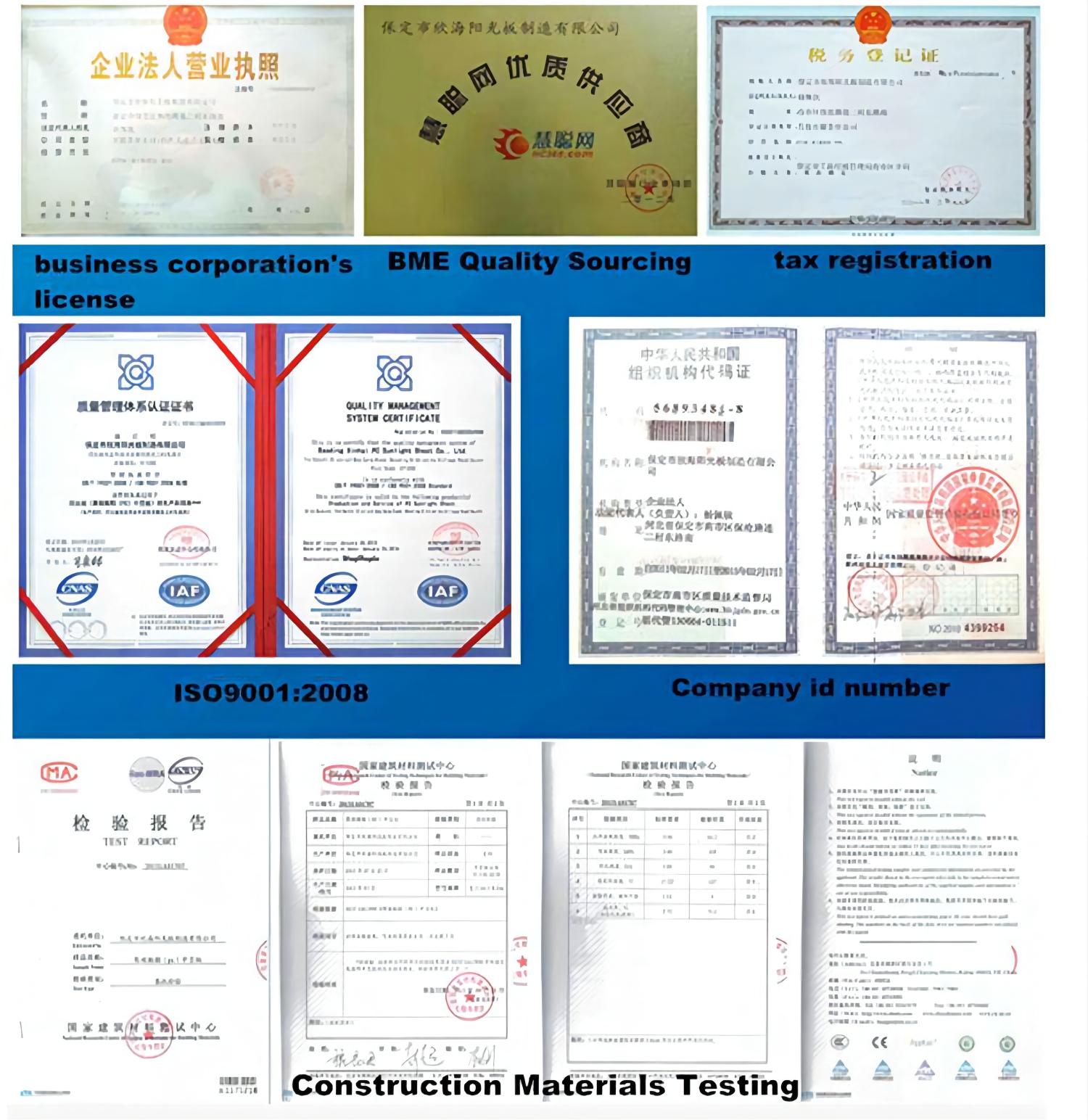

Testing and certification: Child protective packaging is usually tested to ensure that it meets the required child protection standards. Manufacturers often provide documentation or certification to confirm compliance.

Storage and handling: Proper storage and handling of child resistant zipper flat bags is essential to maintain their effectiveness. Make sure they are stored out of reach of children and kept in a cool, dry place to prevent damage to the closing mechanism.

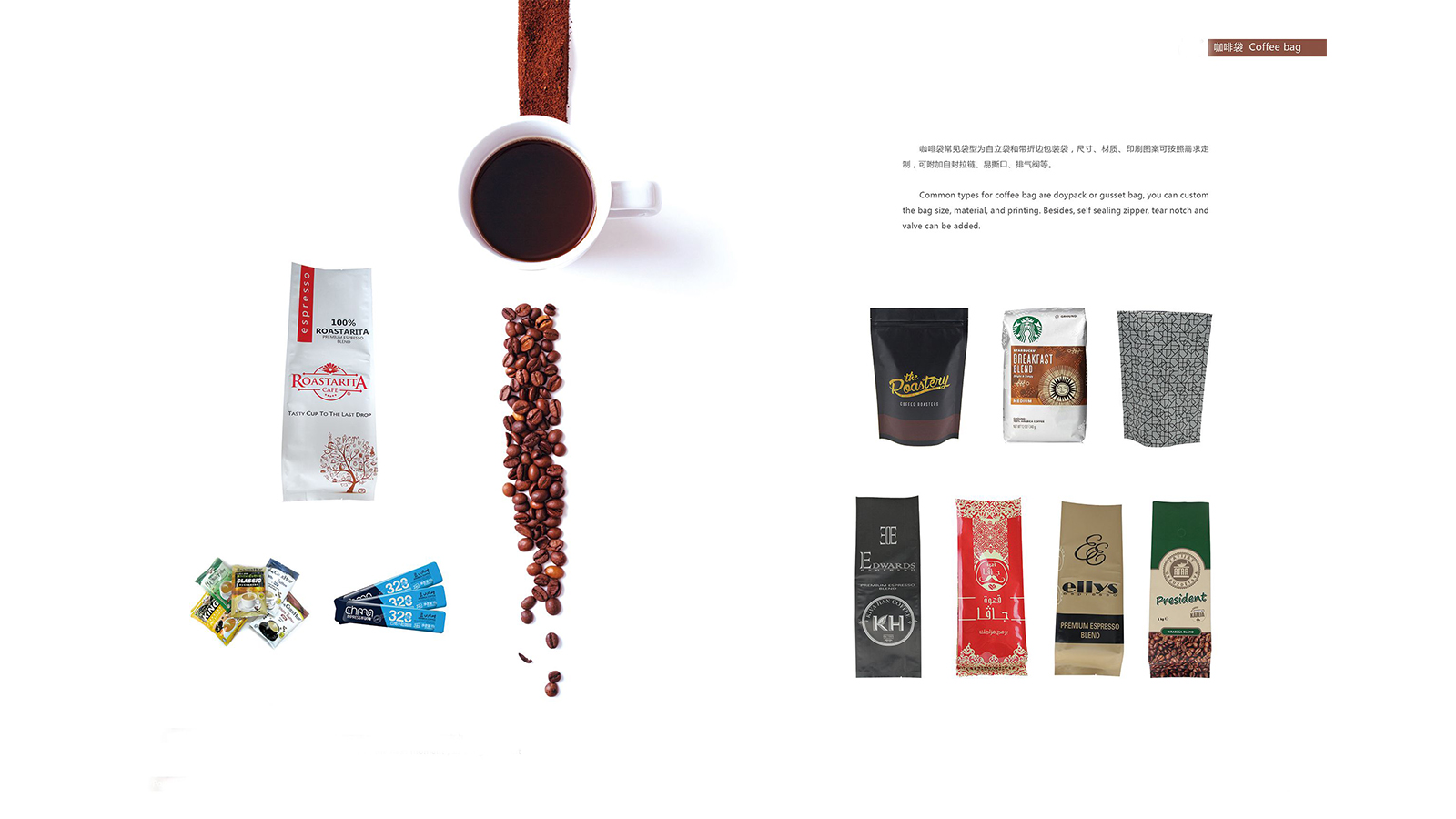

We also have the following range of bags for your reference.

We are a factory, which locates Liaoning Province of China, welcome to visit our Factory.

For ready made products, the MOQ is 1000 pcs, and for customized goods, it depends on the size and printing of your design. Most of the raw material is 6000m, MOQ=6000/L or W per bag, usually about 30,000 pcs. The more you order, the lower the price will be.

Yes, that's the main work we do. You can give us your design directly, or you can provide the basic information to us, we can make free design for you. Besides, we also have some ready made products, welcome to inquire.

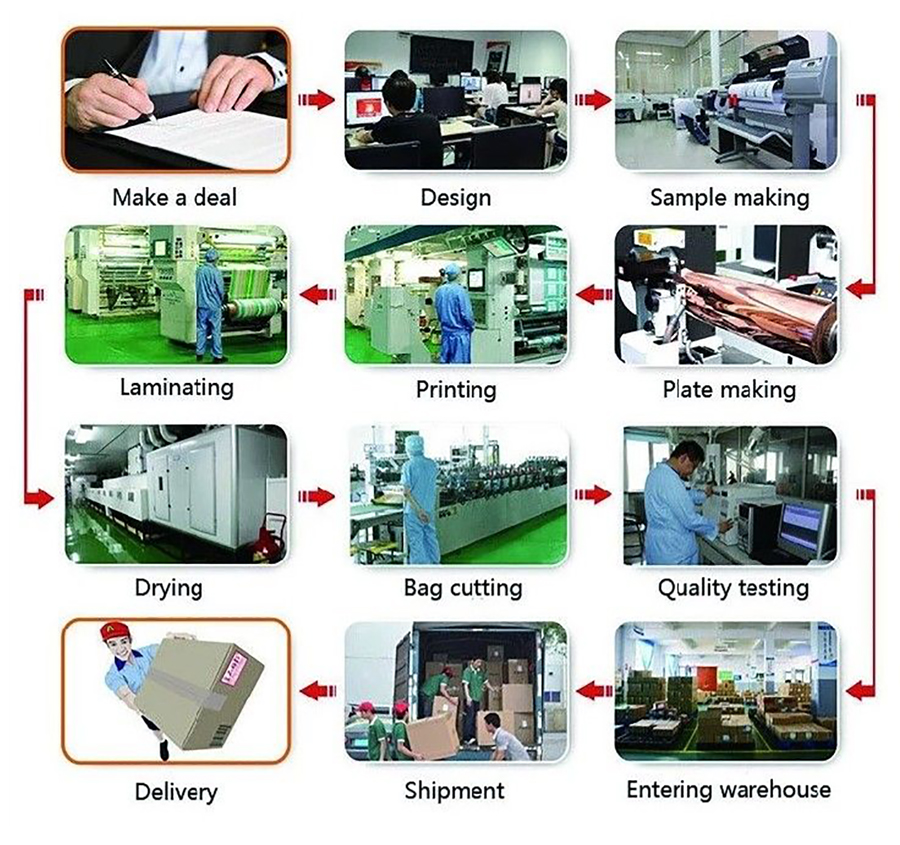

That will depend on your design and quantity, but usually we can finish your order within 25 days after we get the deposit.

First pls tell me the usage of the bag so that i can suggest you the most suitable material and type, eg, for nuts, the best material is BOPP/VMPET/CPP, you can also use craft paper bag, most type is stand up bag, with window or without window as you require. If you can tell me the material and type you want, that will be best.

Second, the size and thickness is very important, this will influence the moq and cost.

Third, the printing and color. You can have at most 9 colors on one bag, just the more color you have, the higher the cost will be. If you have the exact printing method, that will be great; if not, pls provide the basic information you want to print and tell us the style you want, we will do free design for you.

No. Cylinder charge is a one time cost, next time if you reorder same bag same design, no more cylinder charge need. Cylinder is based on your bag size and design colors. And we will keep your cylinders for 2 years before you reorder.